SW North America, Inc.

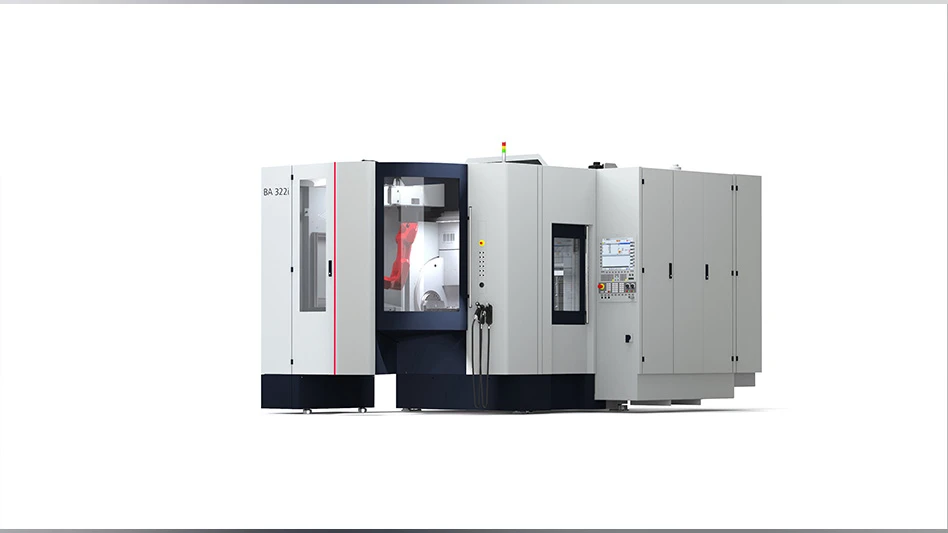

SW North America, Inc.’s BA 322i is designed to function as an independent manufacturing cell that can store enough workpieces for an entire shift. This twin-spindle horizontal CNC machining center produces twice the output while using less floor space and less energy. The BA 322 is available with a loading module featuring an integrated 6-axis robot and vertical workpiece storage. The double swivel carrier enables loading and unloading in parallel to machining time. The vertical workpiece storage is conveniently located to the side and has been trimmed down to require minimal space. The BA 322i has a work area of 300 x 450 x 375 mm on the X-, Y-, and Z-axis. The BA 3 series features the stable monoblock construction in combination with the box-in-box 3-axis unit, 1 or 2 worktables, and 1, 2 or 4 horizontal spindles.