Mantle

Mantle, the leader in automated toolmaking systems, announced software update that delivers substantial performance enhancements to its customers. This update increases production throughput by up to 20% while introducing enhanced surface finish on downfacing surfaces. Mantle also announced increased adoption from leading OEMs, injection molders, and moldmakers.

Manufacturers using Mantle’s technology are experiencing immediate benefits, with Elite Mold & Engineering CEO Paul Patrash noting its transformative impact on toolmaking.

"Implementing Mantle's Automated Toolmaking System has been transformative for our operations at Elite Mold," says Paul Patrash, CEO of Elite Mold & Engineering. "The technology has enabled us to significantly increase our production capacity while simultaneously reducing lead times for our customers. One of the most substantial benefits has been the dramatic reduction in our reliance on sinker EDM machines, which has streamlined our workflow and improved our operational efficiency. With this latest software update delivering up to 20% faster printing speeds, we can produce precision tooling even more quickly than before, further expanding the overall capacity of our toolroom. In today's competitive manufacturing environment, Mantle's technology provides us with a critical edge that directly translates to better service for our clients."

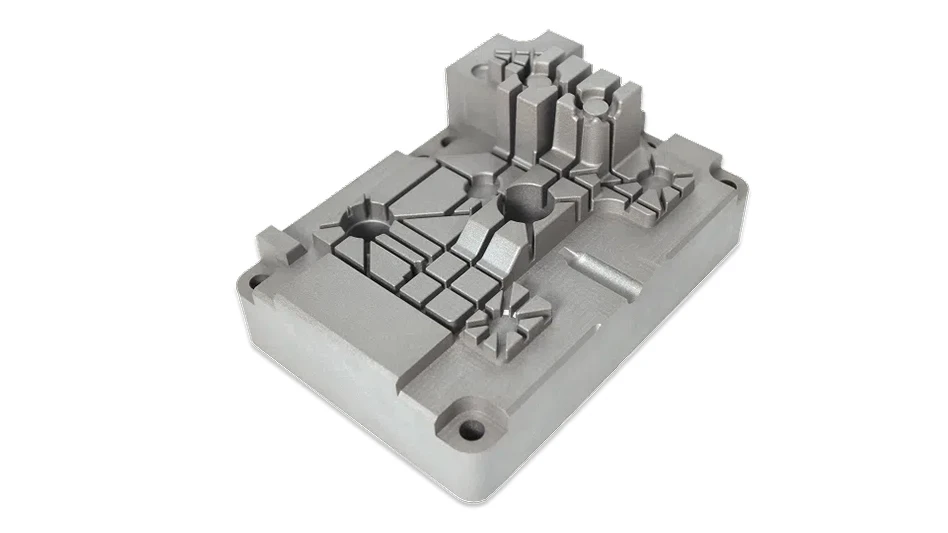

The software update extends Mantle’s industry-leading surface finish quality to downfacing surfaces and undercuts in molds, sliders, and other complex tools. This enhancement allows manufacturers to create tooling components that go directly to molding with even fewer post-processing requirements, further reducing lead times and labor costs.

Mantle’s automated toolmaking system continues to gain traction among companies committed to making toolmaking a strategic advantage for their business.

Edwards Lifesciences and Intricon, prominent medical device manufacturers, have integrated Mantle’s technology into their toolmaking operations to accelerate product development timelines.

Leading injection molders and moldmakers have not only implemented Mantle’s solution to enhance their internal toolmaking operations but have also expanded their business models to offer Mantle as a service. Injection molders Elite Mold & Engineering, Four Square/TRE, along with injection moldmaker Buss Precision Mold, now provide their customers with access to Mantle’s automated toolmaking system, allowing a broader range of manufacturers to benefit from faster lead times, superior surface finishes, and reduced costs.

These forward-thinking companies employ Mantle’s technology to address key business imperatives. The system accelerates product development and reduces time-to-market by expediting the delivery of First-out-of-Tool (FOT) parts. Manufacturers often reduce tooling lead times by over 50%, resulting in substantial cost savings compared to conventional methods.

Particularly notable is how Mantle’s technology helps companies expand their toolmaking capacity during an extended period of skilled labor shortages. Manufacturers can optimize their existing workforce by automating complex processes that traditionally require extensive manual intervention while maintaining or increasing production output.