Yuan Jing Precision Company Ltd. (YJP)

Yuan Jing Precision Company Ltd. (YJP) is a leading name in the field of high-precision engineering, offering cutting-edge solutions for defense and military applications. With decades of manufacturing experience, YJP has successfully developed a comprehensive suite of mission-critical components and systems that meet the rigorous demands of modern defense technology. Through a commitment to precision, customization, and reliability, Yuan Jing positions itself as a strategic partner for military contractors, defense integrators, and national security institutions.

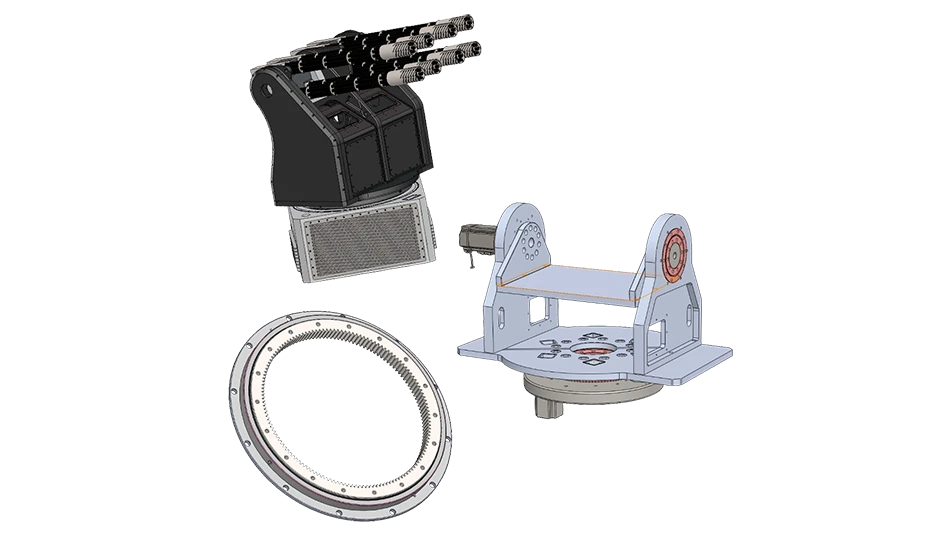

High-precision, high-load-capacity bearings for defense

One of YJP’s flagship contributions to the defense sector is its M4 turret bearing, engineered specifically for harsh environments such as coastal regions, acidic atmospheres, and high-temperature zones. These bearings are designed to endure extreme stress while maintaining high rotational accuracy and structural integrity. The use of special coatings ensures excellent anti-corrosion performance, prolonging the service life of equipment operating under adverse environmental conditions.

Moreover, dual-sided seals constructed from high-hardness composite rubber provide outstanding protection against dust, moisture, and contaminants, while also reducing rotational resistance. These bearings are also lubricated with high-temperature and acid-resistant grease, making them highly reliable in chemically aggressive or heat-intense conditions.

Internal and external gears & cross roller bearing technology

YJP employs advanced internal gear design, where machining is centered precisely on the track’s axis. Using coordinate measuring machines (CMM), YJP ensures perfect alignment between the gear pitch center and the bearing track—essential for turret systems requiring pinpoint accuracy in repeated movement.

Complementing this is YJP’s cross-roller bearing system, which is compact yet offers high torsional stiffness and positioning accuracy. It’s an ideal solution for rotating platforms such as gun turrets and radar systems where space is limited but precision is non-negotiable.

Structurally sound and mission-ready

YJP also manufactures solid turret systems, integrating multiple disciplines such as mechanical design, material engineering, and machining accuracy. Turrets are constructed using high-strength aluminum alloy or stainless steel depending on the environmental requirement. These materials are precision-machined to maintain concentricity across moving parts, reducing misalignment and improving firing or tracking accuracy.

Every solid turret is a product of thoughtful engineering that considers load-bearing requirements, rotational speed, vibration resistance, and durability. From the base to the mount, all parts are custom-fabricated to deliver consistent performance, even under repeated high-stress military operations.

Why choose Yuan Jing for defense projects?

YJP distinguishes itself through:

- Integrated manufacturing capabilities: From material sourcing and machining to assembly and testing, all processes are managed in-house to ensure strict quality control.

- Customization & flexibility: Products can be tailored to specific operational parameters including size, load, communication protocols, voltage ranges, and more.

- Proven defense track record: With successful deployments in military-grade turret systems and motion control platforms, YJP brings validated expertise to every project.

- Global readiness: YJP adheres to international quality standards and is capable of supporting global defense contractors with scalable, precision-engineered components.

Latest from Defense and Munitions

- US Navy selects L3Harris Red Wolf for Precision Attack Strike Munition program

- Snowbird Technologies integrates Meltio Engine Blue into containerized hybrid manufacturing system for defense

- Precision Additive's PA-300 LPBF 3D metal printer

- BIG DAISHOWA supports future of manufacturing with Tools for Schools program

- Mission-Ready: Hutchinson Aerospace & Industry achieves CMMC Level 2 certification

- Shotling's anti-drone shotgun

- ACMI breaks ground on first national manufacturing campus in Indiana, pioneering new model for American defense production

- December 2025 U.S. cutting tool shipments totaled $215M