SW North America

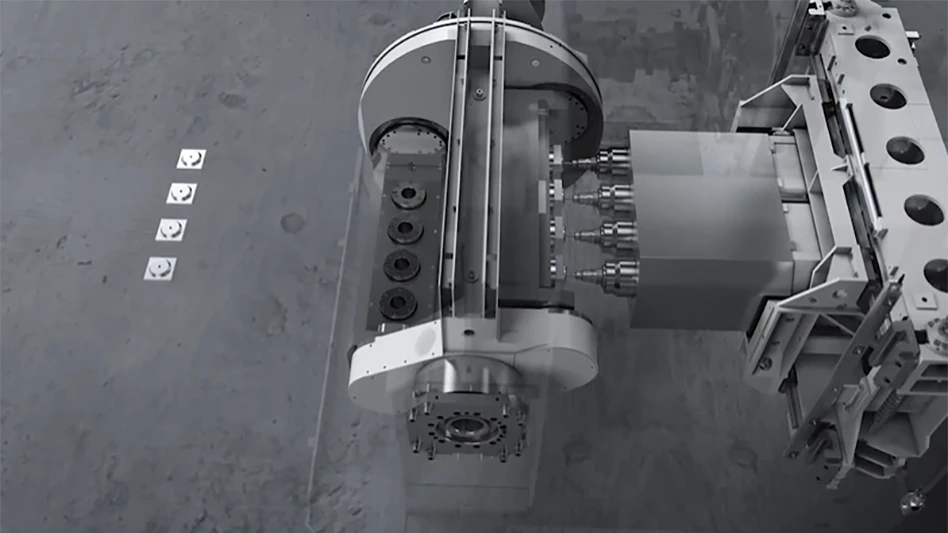

SW North America, a leading supplier of horizontal multi- and single-spindle CNC machining centers, automation, and complete system solutions, will be presenting information on firearms manufacturing automation at the annual SHOT Show in Las Vegas at the Venetian Expo + Caesar’s Forum on January 22 -26, 2024.

Firearms buyers across the United States and around the world are experiencing the positive results of firearms manufacturing automation with SW’s CNC machines, including:

- Reduction in the number of machines and manpower

- Decreased footprints that opens floor space

- Lower energy consumption levels

- Shorter cycle times

- Higher production capacity

“Automation is nothing new. In fact, the technology people at SW North America have been working to perfect firearms manufacturing automation for decades now,” says Andrew Rowley, General Sales Manager, SW North America. “Our methods are tested and trusted, backed by a team that is steeped in firearms manufacturing knowledge to produce winning results, increase productivity, and provide sustainable growth for our current customers.”

Increasing expectations in firearms manufacturing

Firearms manufacturers can expect these key advantages in implementing SW machines:

- Consolidation of equipment (multi-spindle machining) and the integration of proven processes

- Simple integration into the production chain

- Cost-effective, continuous traceable production

- Expertise with ITAR and FFL regulations

“SW machines are making automation easy, with a user-friendly experience and hands-on training included with install,” says Rowley. “This alleviates the headache of skills gaps that so many manufacturers are plagued with today. With SW machines, manufacturers can do more with less.”

Find more information at http://firearms.sw-machines.com/ or visit SW at Booth 51603 in the Supplier Pavilion on January 22-23 or at Booth 10749 in the IWA Pavilion on Level 2 of the Venetian from January 22-26, 2024.

Latest from Defense and Munitions

- Mitsui Seiki USA building new Innovation and Technology Center in Franklin Lakes, New Jersey

- RTX's Raytheon to equip U.S. Air Force autonomous fighter jet with PhantomStrike radar

- EMCO Mecof's Powermill G3 HPC3 gantry milling machine

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers

- OnRobot hosting Automation Roadmap event in Dallas

- A look at the latest in the defense industry

- November 2025 U.S. cutting tool orders total $206.1 million

- Firehawk Aerospace expands U.S. rocket manufacturing with Mississippi facility acquisition