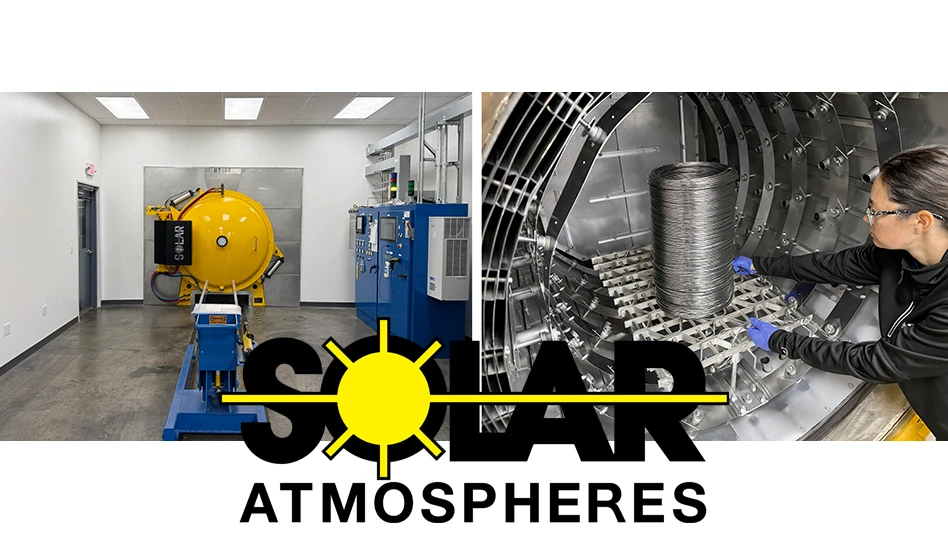

Solar Atmospheres

This installation marks the second all-metal hot zone vacuum furnace added to the climate-controlled processing area at Solar Atmospheres’ Hermitage, Pennsylvania facility. The new system significantly expands the company’s capacity to heat treat highly sensitive materials such as precipitation-hardened stainless steels, nickel-chrome-based superalloys, titanium, and niobium.

Engineered for precision and performance, the furnace incorporates strategically placed isolation valves, an oversized main valve, a high-capacity diffusion pump, and a polished stainless-steel chamber. Together, these features create an ultra-clean processing environment that meets the stringent demands of the aerospace and medical industries. Capable of achieving vacuum levels below 5 x 10⁻⁶ Torr, the system ensures bright, contamination-free results.

“The all-metal vacuum furnace plays a critical role in delivering the purest possible processing environment,” says Michael Johnson, Sales Director at Solar Atmospheres of Western Pennsylvania. “This level of cleanliness and control results in pristine end products that meet the most demanding industry standards. We’re proud to partner with the engineers at Solar Manufacturing to bring this advanced technology to fruition.”

Latest from Defense and Munitions

- Defense and Munitions Online Exclusive with Keeper Security

- Mazak will show shops how to drive production at Dallas open house event

- Sandvik Coromant's CoroTurn Plus turning adapter

- US Navy selects L3Harris Red Wolf for Precision Attack Strike Munition program

- Snowbird Technologies integrates Meltio Engine Blue into containerized hybrid manufacturing system for defense

- Precision Additive's PA-300 LPBF 3D metal printer

- BIG DAISHOWA supports future of manufacturing with Tools for Schools program

- Mission-Ready: Hutchinson Aerospace & Industry achieves CMMC Level 2 certification