QuesTek Innovations

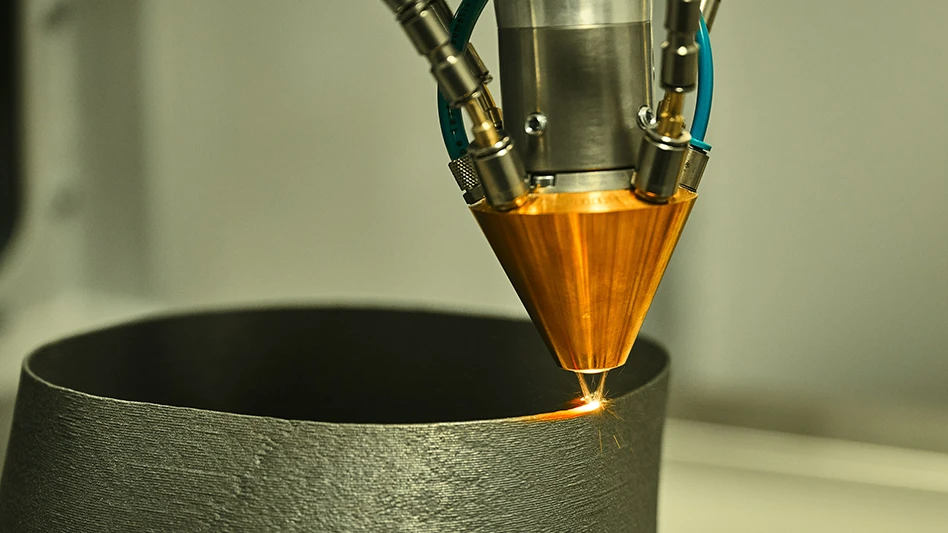

QuesTek Innovations, the primary operating arm of QuesTek International LLC, was awarded three new patents for proprietary alloys specifically designed for additive manufacturing (AM).

"We’re honored to announce these patent awards," says QuesTek COO Bill Mahoney. "While QuesTek is delivering its overarching digital strategy to the market, one of our strategic initiatives is to continue to position our Materials by Design technology at the forefront of materials innovation. The patents on these remarkable proprietary materials reinforce our technology's leadership position in Integrated Computational Materials Engineering (ICME) overall, and specifically for additive manufacturing."

The following patented QuesTek materials allow for higher performance across multiple applications:

1. Auto-tempering steel (US11780014B2): A printable high-strength, high-toughness, low-carbon martensitic steel that exploits the "auto-tempering" phenomenon during the additive manufacturing process to achieve high performance, including low-temperature toughness, without the need of any post-heat treatment. The application of the alloy includes, but is not limited to, naval structural applications, as well as ballistic and cryogenic applications.

2. Al—Mg—Si alloy (US11773468B2): An aluminum alloy improved for additive manufacturing so that it resists hot tearing during the build process and retains superior mechanical performance for high temperatures.

3. Titanium alloy (US11780003B2): A modification of QuesTek's patented castable titanium alloy for additive manufacturing that retains more strength and ductility than cast Ti-6Al-4V. Desired performance comes in both wire and powder-based AM processes with great process flexibility, resulting in equiaxed grain structure with isotropic mechanical properties.

Latest from Defense and Munitions

- US Navy selects L3Harris Red Wolf for Precision Attack Strike Munition program

- Snowbird Technologies integrates Meltio Engine Blue into containerized hybrid manufacturing system for defense

- Precision Additive's PA-300 LPBF 3D metal printer

- BIG DAISHOWA supports future of manufacturing with Tools for Schools program

- Mission-Ready: Hutchinson Aerospace & Industry achieves CMMC Level 2 certification

- Shotling's anti-drone shotgun

- ACMI breaks ground on first national manufacturing campus in Indiana, pioneering new model for American defense production

- December 2025 U.S. cutting tool shipments totaled $215M