Photo by Senior Airman Mikaela Smith

Pratt & Whitney, an RTX business, secured a three-year contract valued up to $1.5 billion to sustain F119 engines, which power the U.S. Air Force's F-22 fighter jets. The contract will improve readiness and reduce costs for an F119 fleet of more than 400 engines that have flown over 900,000 engine flight hours.

"The F119's readiness and reliability rates have never been more important, and we are improving both while lowering lifecycle costs," says Jill Albertelli, president of Military Engines at Pratt & Whitney. "We are committed to helping our U.S. Air Force customer maintain the F-22's combat edge."

The F-22 Raptor's two F119 engines generate over 35,000 pounds of thrust, enabling altitudes above 65,000 feet with unmatched speed and agility. Unlike many fighter jets, the F-22 can achieve and maintain supersonic speeds without afterburners, a strategic feature known as supercruise that conserves fuel and extends operational range.

Pratt & Whitney has lowered costs on its F119 engines through its on-going Usage Based Lifing program, which leverages real-time data to enhance maintenance efficiency and extend engine life; while also improving the engine's kinematic performance with an engine control schedule update. This latest contract will continue these readiness and cost savings efforts with a focus on safety, availability, simplicity of maintenance, and modernization initiatives.

Latest from Defense and Munitions

- HII places second Nikon SLM Solutions NXG 600E order

- L3Harris demonstrates interoperable network to unify Department of War and U.S. government agencies

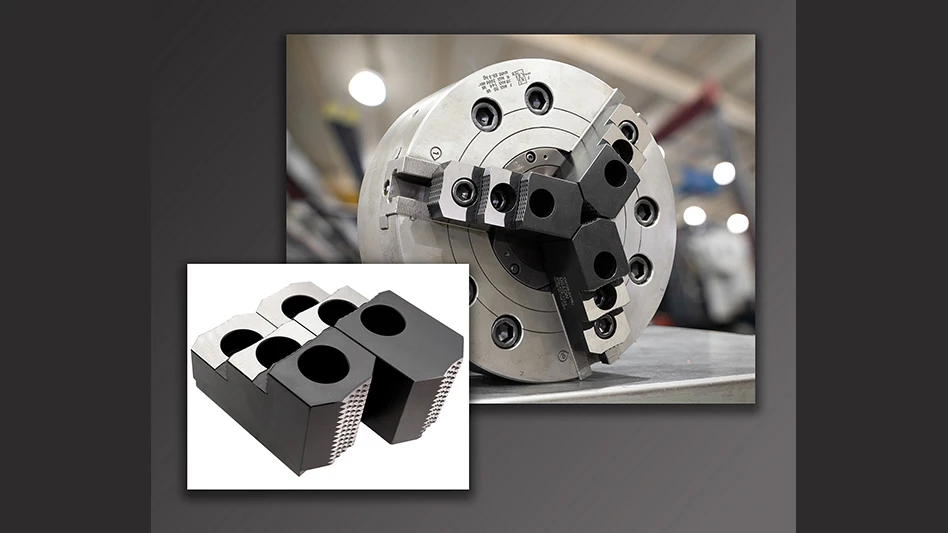

- Platinum Tooling/Heimtec's speed increasers for lathes and Swiss-style machines

- U.S. Army awards Persistent Systems contract for $87.5 Million supporting Next-Generation Command and Control prototype

- Northrop Grumman successfully tests Mk 72 solid rocket motor for U.S. Navy

- Orqa announces Global Manufacturing Program to expand drone production to 1 million units annually

- Lantek's v.45 Suite software

- Kratos issues letter of intent for 60 full rate production Zeus hypersonic system rocket motors from L3Harris