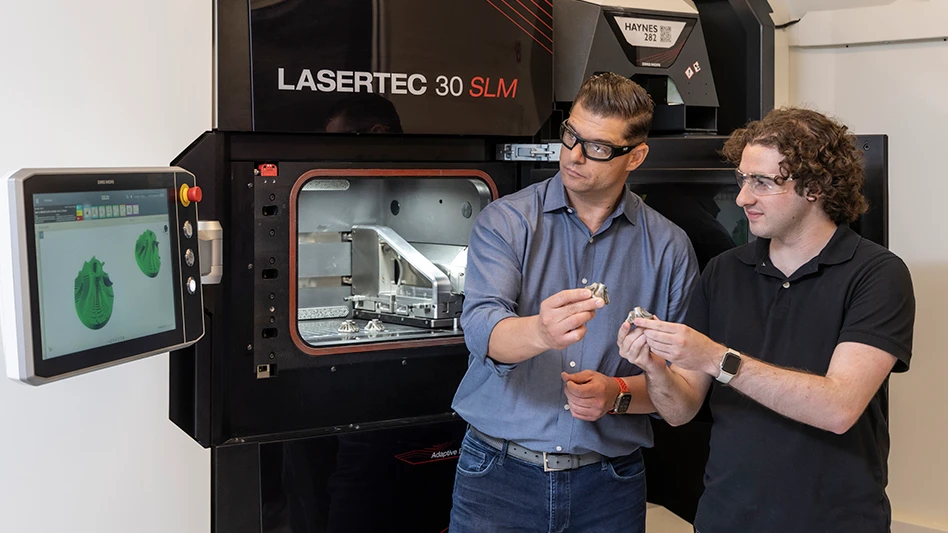

Courtesy of Rowan University

The rapid development of artificial intelligence and the usability of large language models have promised to transform industries on a large scale, but first engineers must figure out how to integrate intelligent systems with real-world manufacturing methods.

To accomplish that goal, Rowan University’s Digital Engineering Hub (DEHub) is merging smart technology with advanced manufacturing methods through its well-equipped lab launched this fall.

Housed at Henry M. Rowan College of Engineering’s Rowan Hall and directed by Antonios Kontsos, Ph.D., the DEHub lab can digitize real-world objects, as well as creating new objects based on human- or machine-engineered designs.

The lab features 3D polymer and metal printers, 3D scanners for digitizing existing objects, and devices for mechanical sensing and testing. DEHub’s key piece of equipment is DMG MORI’s LASERTEC 30 SLM US, the first metal additive manufacturing equipment of its kind.

Designed and assembled in the United States, the 3D metal printer uses a high-powered laser to melt and fuse thin layers of metal powder to create a solid component. The machine’s distinguishing features include its adaptive beam control, improved production process and interconnectivity, allowing the detection—and correction—of flaws in real time during the construction process.

The lab’s processing power is fueled by a highly secure computer cluster named Pythia, after the Oracle of Delphi in ancient Greece. Purpose-built to drive the lab’s systems, Pythia can receive and process terabytes of information instantly.

“We are the first academic research group in the world to connect a supercomputer for this type of machine,” says Kontsos, the Henry M. Rowan Foundation Endowed Professor in the Department of Mechanical Engineering. “The data we’re collecting—such as part temperature and laser information—is in the order of terabytes, so we need the computational power coupled with live -streaming capabilities to synchronously store and process this information.”

Focused first on federally funded research for the Defense Advanced Research Projects Agency, DEHub aims to work across a wide range of manufacturing sectors, including the defense, manufacturing, pharmaceutical, biotechnology, energy and civil infrastructure as well as robotics industries.

Interest is already high. DEHub’s recent launch event attracted representatives from companies as far away as California, Texas and even Australia.

“Our horizon is not to improve the Glassboro economy only,” Kontsos says, “We want to improve it by being a resource worldwide.”

Latest from Defense and Munitions

- SMW Autoblok Corporation appoints Brandon Mathis as National Sales Manager

- Bodycote expands U.S. aerospace and defense footprint with acquisition of Spectrum Thermal Processing

- AM Solutions’ automated surface finishing of 3D-printed parts

- Joint Interagency Task Force 401 expands counter-drone training

- Davie Defense awarded U.S. Coast Guard contract to build five Arctic Security Cutters

- Dillon Manufacturing’s Jaw Force Gauges

- Georgia Southern University partners with METAL to advance workforce training in metalworking and manufacturing

- AM General sells first HUMVEE Hawkeye 105mm mobile howitzer systems as part of three-year contract