MISCO Speaker Company

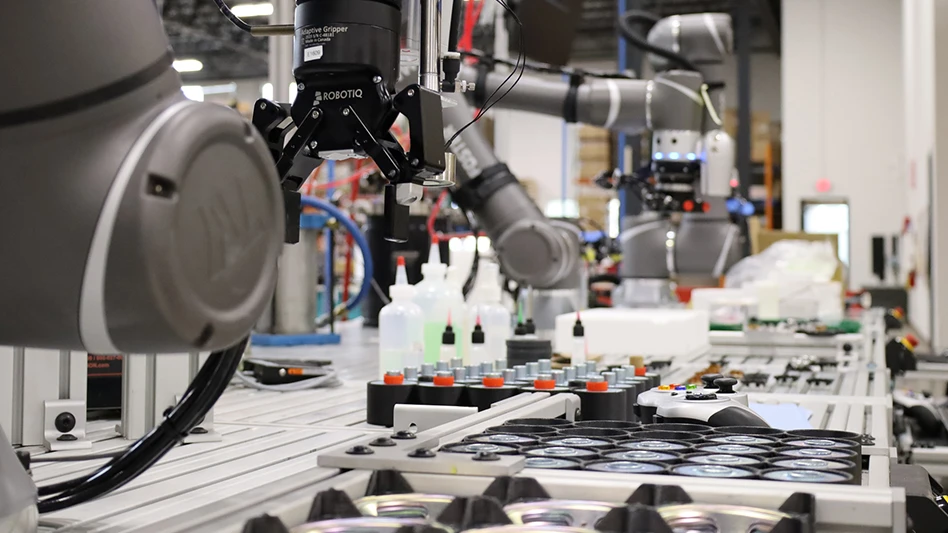

MISCO Speaker Company, now celebrating over 75 years in operation, has announced the launch of collaborative robotics (cobot)-assisted micro-speaker manufacturing at its Energy Park facility. This development positions MISCO as the first U.S. manufacturer to mass-produce micro-speakers — audio components under two inches in diameter — using cobot technology.

Micro-speakers are integral to defense communication systems, medical devices, and other critical applications that can’t afford delays or quality issues. Historically, these components have been manufactured overseas due to the labor-intensive nature of production. MISCO’s adoption of cobots enables precision assembly and scalable output while enhancing supply chain security for industries requiring U.S.-made components.

“Customers in sectors such as defense and medical are increasingly prioritizing domestic sourcing for critical components,” says Dan Digre, MISCO president and CEO. “Our investment in cobots makes U.S.-based mass production of micro-speakers viable, ensuring quality and traceability for mission-critical applications.”

MISCO’s Energy Park facility features advanced capabilities, including an acoustical testing lab, environmental testing chambers for extreme conditions, and 3D printing for rapid prototyping. The company’s ISO 9001:2015-certified processes ensure adherence to international quality standards. Additionally, MISCO’s domestic operations comply with International Traffic in Arms Regulations (ITAR), supporting defense contractors with secure and reliable solutions.

Beyond defense applications, micro-speakers are used in aerospace systems, wearable devices, IoT products, and portable communications equipment. MISCO’s reshoring efforts aim to address growing demand for secure and compliant U.S.-manufactured components across multiple industries.

Latest from Defense and Munitions

- SMW Autoblok Corporation appoints Brandon Mathis as National Sales Manager

- Bodycote expands U.S. aerospace and defense footprint with acquisition of Spectrum Thermal Processing

- AM Solutions’ automated surface finishing of 3D-printed parts

- Joint Interagency Task Force 401 expands counter-drone training

- Davie Defense awarded U.S. Coast Guard contract to build five Arctic Security Cutters

- Dillon Manufacturing’s Jaw Force Gauges

- Georgia Southern University partners with METAL to advance workforce training in metalworking and manufacturing

- AM General sells first HUMVEE Hawkeye 105mm mobile howitzer systems as part of three-year contract