Lyten

Lyten, the supermaterial applications company and global leader in lithium-sulfur batteries, announced a new national security-focused initiative to support the growing demand for high-endurance, wide-operational-radius drones for defense applications. The initiative is built on a next-generation drone energy storage system powered by Lyten’s ultra-lightweight lithium-sulfur (Li-S) batteries. Lyten is dedicating production capacity in its California manufacturing facilities to meet the unique needs of the U.S. defense, unmanned aerial vehicle (UAV), and satellite sectors.

Lyten’s U.S.-sourced and manufactured lithium-sulfur batteries are uniquely positioned to help the Department of Defense meet two urgent modernization imperatives:

- Reducing dependence on foreign and adversarial supply chains for critical minerals, components, and batteries

- Enabling the deployment of lighter, longer range, and more capable UAV platforms

“Defense initiatives increasingly rely on unmanned, autonomous systems, yet nearly all these systems are powered by raw materials and batteries sourced from geopolitical rivals,” says Dan Cook, Lyten Co-Founder and CEO. “We built Lyten’s lithium-sulfur battery platform to solve exactly this problem – to provide lightweight, high performance battery power that is locally sourced and locally manufactured in the United States.”

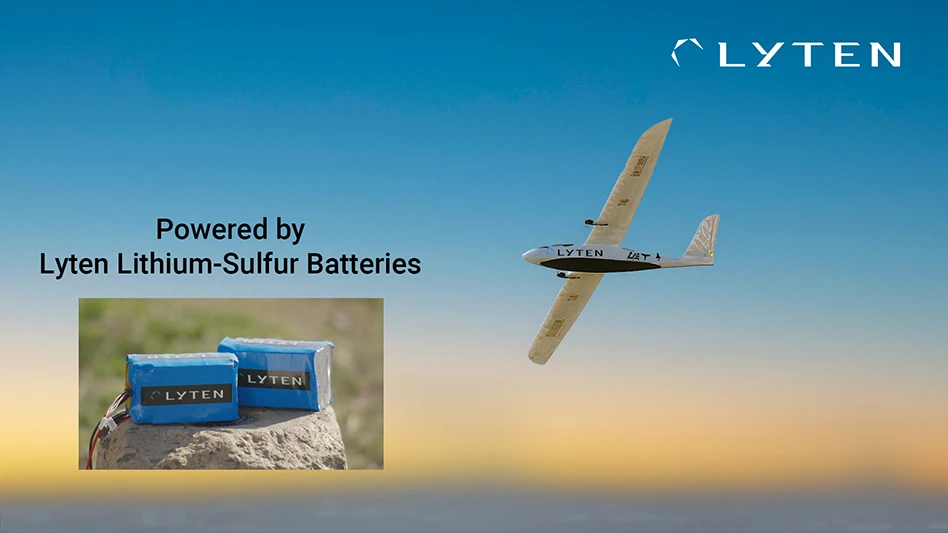

In a newly released demonstration flight video (watch here: https://www.youtube.com/watch?v=W856uYx2fMM), Lyten showed its lithium-sulfur battery powering a U.S.-built, 3D-printed UAV. The drone was made by Titan Dynamics, utilizing a battery pack designed by Upgrade Energy, both located in Los Angeles. The successful flight of Titan’s 8.5ft wingspan drone in Palos Verdes, California demonstrated flight time capability of over 3 hours while executing a wide range of maneuvers, at speeds of up to 86mph. Lyten’s next upcoming drone battery release is targeting up to 8 hours of flight time on the Titan Dynamics platform.

Lyten’s lithium-sulfur batteries are free from nickel, manganese, cobalt, and graphite — minerals dominated by Chinese supply chains — enabling a secure, National Defense Appropriations Act (NDAA)-compliant energy solution for defense platforms. Lithium-Sulfur batteries, with their higher energy density, are designed to support longer flights, heavier payloads, and extended operational range.

“Lightweight propulsion is of critical importance to so many industries,” says Celina Mikolajczak, Lyten’s Chief Battery Technology Officer. “Satellites, drones, EVs, and micromobility can all dramatically improve in performance with lighter weight batteries. We have designed the lithium-sulfur battery platform to provide this lightweight performance, while avoiding materials subject to growing geopolitical and supply chain constraints.”

Lyten is currently taking orders for its latest lithium-sulfur battery for drones. Lyten previously announced a contract with the Defense Innovation Unit to demonstrate Lyten’s lithium-sulfur batteries on the International Space Station, slated for launch later this year. Lyten’s ultra-lightweight solution is now achieving over 3000 cycles for satellite applications.

Latest from Defense and Munitions

- SMW Autoblok Corporation appoints Brandon Mathis as National Sales Manager

- Bodycote expands U.S. aerospace and defense footprint with acquisition of Spectrum Thermal Processing

- AM Solutions’ automated surface finishing of 3D-printed parts

- Joint Interagency Task Force 401 expands counter-drone training

- Davie Defense awarded U.S. Coast Guard contract to build five Arctic Security Cutters

- Dillon Manufacturing’s Jaw Force Gauges

- Georgia Southern University partners with METAL to advance workforce training in metalworking and manufacturing

- AM General sells first HUMVEE Hawkeye 105mm mobile howitzer systems as part of three-year contract