Lantek

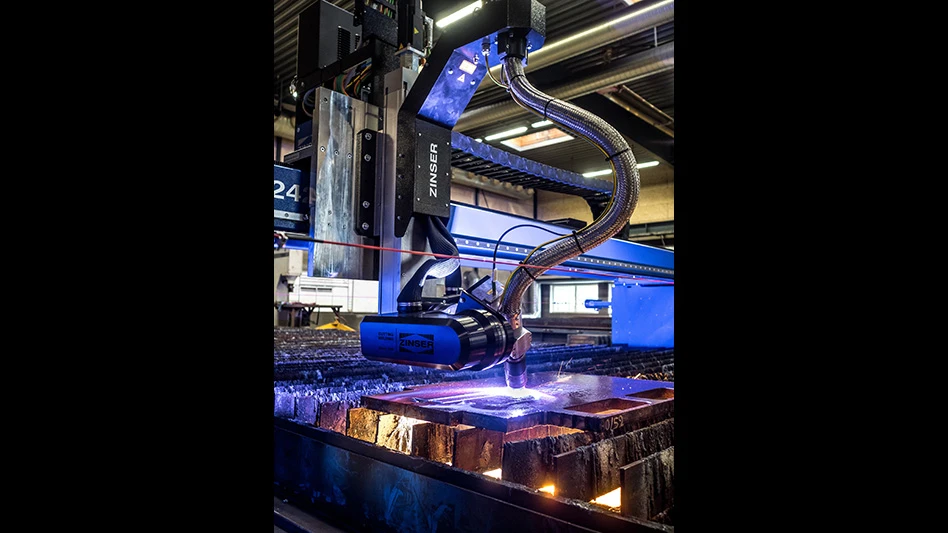

Lantek, a global leader in software solutions for the sheet metal industry, and ZINSER, a renowned German manufacturer of state-of-the-art sheet metal and pipe cutting systems, have jointly developed an innovative solution that revolutionizes bevel cutting in pre-cut parts. This collaboration allows customers to improve precision without interrupting production, achieving greater efficiency and higher-quality finishes.

Uninterrupted bevel cutting: a new production approach

Traditionally, bevel cutting was performed within the nesting process, often causing issues such as collisions, cutting inaccuracies, or production slowdowns. The industry is now shifting towards a more efficient approach: first, parts are cut on a high-production machine, and then those requiring bevels are transferred to a dedicated bevel-cutting machine. This approach reduces downtime in the main cutting process while improving control over bevelling operations. At the core of this solution is ZINSER’s sophisticated part recognition system. Their machines use advanced measurement technologies (such as optical cameras, contact sensors, and multi-point detection) to accurately identify each part’s geometry and orientation, enabling precise and reliable bevel cutting.

Advanced software for seamless integration

Lantek’s contribution to this development has been key to enabling seamless integration between software and machine. Through a custom-developed postprocessor for ZINSER machines, Lantek’s software uses sensory data to accurately calculate each part’s position and orientation, automatically adjusting the cutting parameters to ensure precise execution.

“Our development helps customers optimize workflow and reduce material waste without compromising bevel-cutting quality,” says Francisco Pérez, OEM Channel Director at Lantek. “This technology delivers more precise cuts and improved production times, ensuring smooth integration with the rest of the manufacturing process.”

Tangible benefits for customers

By integrating Lantek’s software into ZINSER machines, customers can manage bevel cutting more efficiently, particularly for parts with complex geometries. Separating this process from the initial cutting results in a smoother production flow and eliminates unnecessary downtime.

Key benefits of this solution include:

- Higher bevel-cutting precision, thanks to the exact recognition of each part’s position.

- Reduced downtime, as complex operations are handled by a specialized machine without disrupting primary production.

- Optimized workflow, with seamless integration between cutting and bevelling.

- Compatibility with various part recognition methods, such as optical and contact sensors, enabling greater flexibility in production.

A step towards intelligent automation

This solution has already been successfully implemented in various facilities across Europe, establishing itself as an innovative approach to optimizing bevel cutting in the sheet metal industry. Its design ensures seamless integration with different cutting and automation systems, making it applicable to ZINSER industries such as metal structures, shipbuilding, and heavy machinery manufacturing.

With a focus on precision, efficiency, and reduced downtime, this technology represents a major step toward autonomous manufacturing, where the combination of advanced software and specialized machinery optimizes production without compromising cut quality.

Latest from Defense and Munitions

- SMW Autoblok Corporation appoints Brandon Mathis as National Sales Manager

- Bodycote expands U.S. aerospace and defense footprint with acquisition of Spectrum Thermal Processing

- AM Solutions’ automated surface finishing of 3D-printed parts

- Joint Interagency Task Force 401 expands counter-drone training

- Davie Defense awarded U.S. Coast Guard contract to build five Arctic Security Cutters

- Dillon Manufacturing’s Jaw Force Gauges

- Georgia Southern University partners with METAL to advance workforce training in metalworking and manufacturing

- AM General sells first HUMVEE Hawkeye 105mm mobile howitzer systems as part of three-year contract