L3Harris Technologies

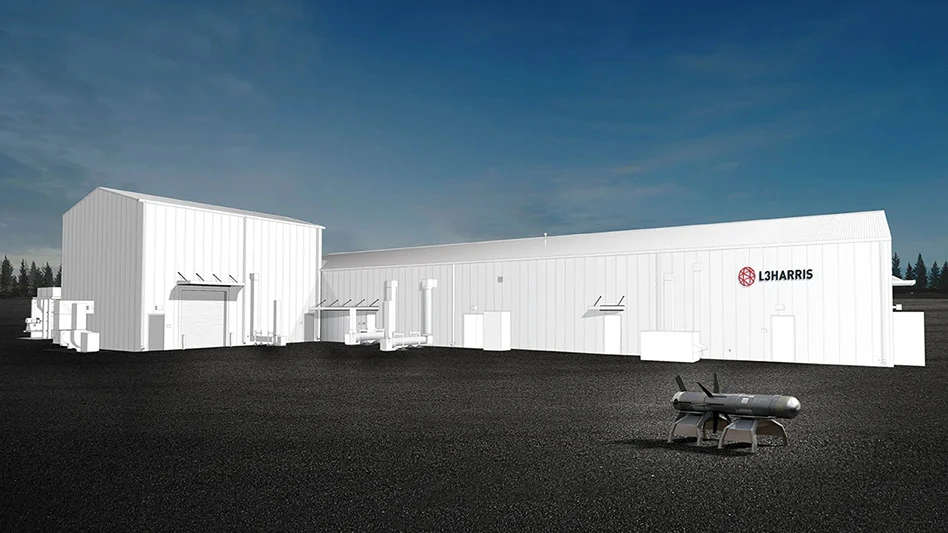

L3Harris Technologies has broken ground on the construction of five new solid rocket motor facilities in Virginia that will boost production to support key national defense programs. The new facilities will incorporate modular factory design, robotic flex cells, automated, progressive casting, and improved handling and assembly throughout the production line.

“L3Harris’ growth in Virginia is another solid example of how we’re expanding our rocket motor manufacturing infrastructure to support the nation’s defense propulsion needs,” says Ken Bedingfield, President, Aerojet Rocketdyne, L3Harris. “Made possible through a Defense Production Act Title III cooperative agreement, this expansion will complement an existing 256,000 square feet of manufacturing space, supporting some of the most advanced propulsion research and production in the world.”

L3Harris’ site in Virginia hosts the company’s Center of Excellence for Propellant Research and Small to Medium-sized Solid Rocket Motor Production. The expansion includes a 12,000ft2, state-of-the-art solid rocket motor cast and assembly facility, as well as a control room, facilities to support mixing and grinding operations and upgrades to the site’s motor testing capabilities. The consolidated cast and assembly building will centralize production of a critical program under one roof, reducing the distance motors travel during manufacturing by 90%.

“L3Harris’ continued expansion in Virginia underscores the Commonwealth’s pivotal role in safeguarding our nation’s security,” says Virginia Gov. Glenn Youngkin. “With a world-class workforce, cutting-edge infrastructure, and a strategic East Coast location, Virginia offers the ideal environment for defense and aerospace leaders like L3Harris to grow and drive innovation for the future.”

“I’m proud of Virginia’s continued leadership in the defense sector, which is made possible in part through crucial investments like L3Harris’ new solid rocket motor facilities,” says Sen. Tim Kaine, D-Va. “I’ll keep looking for opportunities to support Virginia’s robust defense industry—a core pillar of Virginia’s economy and a key component of our military readiness.”

“Thrilled to see L3Harris expand its presence in Virginia and continue to strengthen our defense industrial base,” says Sen. Mark R. Warner, D-Va. “This investment in Orange County will support the world-class research and manufacturing coming out of Virginia, while also creating valuable jobs for American workers.”

“This investment by L3Harris underscores how the Seventh Congressional District, and Virginia overall, remains a great place to build systems critical to our national security. This project will yield exactly the kind of smart, strategic growth we need in the Seventh District to strengthen our national security, rebuild America’s defense industrial base, and build key components for munitions such as the Javelin,” says Rep. Eugene Vindman, D-Va. “As an Army veteran and a member of the House Armed Services Committee, I will prioritize supporting projects that ensure our service members have the tools they need to keep our country safe — while creating more good jobs right here in the Seventh.”

“Investment in key capabilities for domestic defense production is integral to our efforts to continue to support warfighter requirements,” says Greg Davis, Acting Director, Manufacturing Capability Expansion and Investment Prioritization, Office of the Assistant Secretary of Defense for Industrial Base Policy. “It’s also an important component to the Department’s priority of revitalizing the defense industrial base.”

L3Harris is also modernizing and expanding its solid rocket motor production in two other states. The company is constructing new solid rocket motor facilities in Camden, Arkansas, and is transitioning production of inert components for critical missile systems to align with the sites’ core competencies in Huntsville, Alabama. The company is already ramping up production due to digital process improvements as well as new tooling and equipment.

Latest from Defense and Munitions

- SMW Autoblok Corporation appoints Brandon Mathis as National Sales Manager

- Bodycote expands U.S. aerospace and defense footprint with acquisition of Spectrum Thermal Processing

- AM Solutions’ automated surface finishing of 3D-printed parts

- Joint Interagency Task Force 401 expands counter-drone training

- Davie Defense awarded U.S. Coast Guard contract to build five Arctic Security Cutters

- Dillon Manufacturing’s Jaw Force Gauges

- Georgia Southern University partners with METAL to advance workforce training in metalworking and manufacturing

- AM General sells first HUMVEE Hawkeye 105mm mobile howitzer systems as part of three-year contract