GWS Tool Group

The Situation

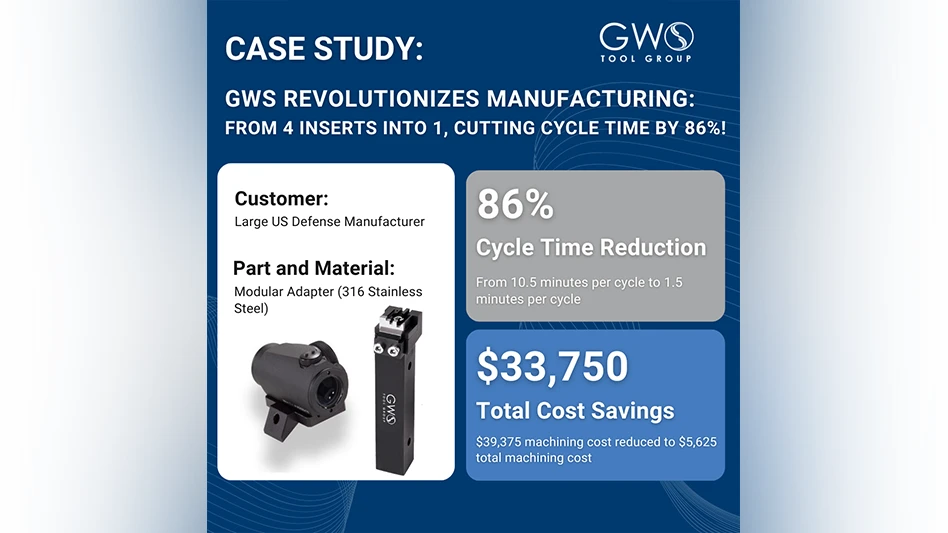

A large US defense manufacturing customer was using four separate ISO standard inserts, to make a singular part. This resulted in a lengthy cycle time of 10.5 minutes per part. With an order for just 3,000 parts, the total machining time was a staggering 525 hours, causing significant production delays and frustrations. Seeking a solution, the client turned to GWS to create a custom insert. They requested the new custom insert combine the four inserts, reduce the cycle time, and speed up the production timeline.

Current Process Results

- 4 ISO Standard Inserts

- Cycle time of 10.5 minutes per part

- Machining time of 525 hours

- $39,375 in total machining cost

New GWS Solution - Singular custom insert

- New cycle time of 1.5 minutes per part

- Machining time down to 75 hours

- Reduced total machining time by 86%

- $5,625 in total machining cost

- Total cost savings of $33,750

Conclusion

GWS rose to the occasion by designing a custom insert that combined the four standard ISO inserts, into one custom insert. We engineered an insert to complete the entire profile in a single “X” (plunge) movement. By consolidating the functionality of the four inserts, we achieved remarkable results, slashing the cycle time by 9 minutes—from 10.5 minutes down to just 1.5 minutes per cycle! This reduction translated to an incredible 450 hours of saved machine time, improving the total machining time from 525 hours to a mere 75 hours (an 86% reduction)! In addition to resolving the customer’s initial issue, our solution also eliminated errors caused by previously needing multiple inserts, minimized tool changes, and significantly enhanced the quality of the part.

Interested in finding out more information about our standard and custom tools? Consider contacting the experts who make Custom Come Standard and let us find the perfect cutting tool for you. Just send us an email at sales@gwstoolgroup.com to get started!

Latest from Defense and Munitions

- SMW Autoblok Corporation appoints Brandon Mathis as National Sales Manager

- Bodycote expands U.S. aerospace and defense footprint with acquisition of Spectrum Thermal Processing

- AM Solutions’ automated surface finishing of 3D-printed parts

- Joint Interagency Task Force 401 expands counter-drone training

- Davie Defense awarded U.S. Coast Guard contract to build five Arctic Security Cutters

- Dillon Manufacturing’s Jaw Force Gauges

- Georgia Southern University partners with METAL to advance workforce training in metalworking and manufacturing

- AM General sells first HUMVEE Hawkeye 105mm mobile howitzer systems as part of three-year contract