Arnold Magnetic Technologies Corporation

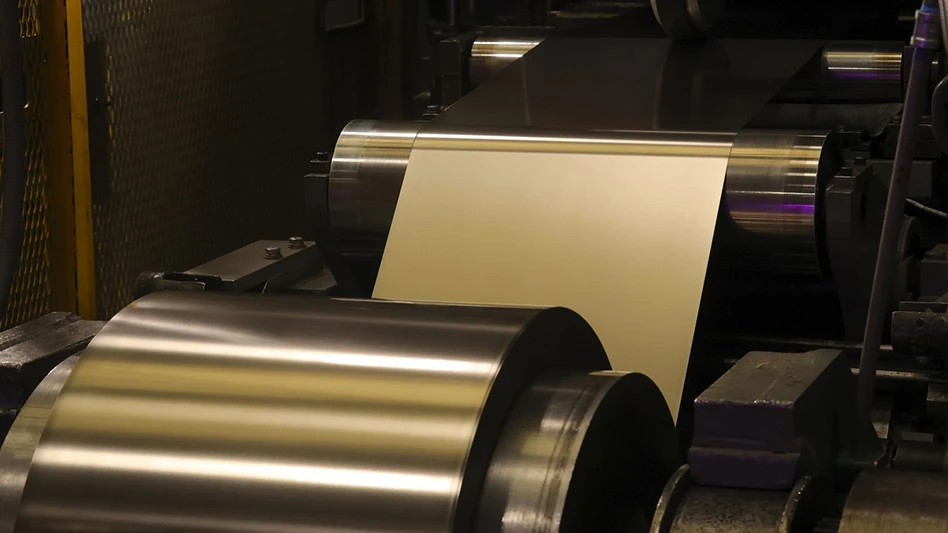

Arnold Magnetic Technologies Corporation, a subsidiary of Compass Diversified and leading global manufacturer of high-performance magnets and precision components, highlights a series of recent significant equipment overhauls and environmental upgrades at its new Precision Thin Metals (PTM) facility. These investments are designed to enhance product quality, improve lead times, and reinforce Arnold’s commitment to environmental stewardship.

Arnold’s PTM operation opened in their new facility in Woodstock, Illinois earlier this year, and has undergone comprehensive upgrades to multiple key pieces of equipment. These overhauls are already delivering measurable improvements in both product quality and delivery timelines, strengthening Arnold’s position as a trusted supplier to critical industries.

https://www.arnoldmagnetics.com/

In addition to equipment enhancements, the new facility incorporates a range of advanced environmental technologies. PTM now utilizes air oxidizers that clean emissions from various equipment, ensuring that approximately 99% of the air released is clean. A closed-loop chiller system has been installed for process cooling water, eliminating the need for continuous freshwater consumption and drastically reducing daily water waste. High-efficiency LED lighting has been implemented throughout the facility, further reducing energy consumption and environmental impact.

PTM has installed a new bromide recycling still, which reduces the need to purchase new degreasing chemicals by approximately 70%. The company has also added a HydroFlo Tech automatic pH balancing filtration system to manage wastewater discharge from the annealing furnace’s wash and rinse tanks.

Arnold’s PTM facility is enhancing its operations through strategic investments in sustainable manufacturing. These upgrades, including advanced environmental controls and critical equipment enhancements, will improve product quality and efficiency while reducing environmental impact. This initiative demonstrates Arnold’s dedication to providing customers with reliable, high-performance materials and solutions that meet contemporary sustainability standards.

Latest from Defense and Munitions

- US Navy selects L3Harris Red Wolf for Precision Attack Strike Munition program

- Snowbird Technologies integrates Meltio Engine Blue into containerized hybrid manufacturing system for defense

- Precision Additive's PA-300 LPBF 3D metal printer

- BIG DAISHOWA supports future of manufacturing with Tools for Schools program

- Mission-Ready: Hutchinson Aerospace & Industry achieves CMMC Level 2 certification

- Shotling's anti-drone shotgun

- ACMI breaks ground on first national manufacturing campus in Indiana, pioneering new model for American defense production

- December 2025 U.S. cutting tool shipments totaled $215M