Large-frame stereolithography printer

The SLA 825 Dual is 3D Systems’ most advanced large-frame SLA printer to date. For customers depending on SLA technology for superior surface finish, accuracy, and reliability, the SLA 825 Dual extends that legacy while creating a pathway for continuous performance and throughput improvements. With a 20% larger build volume of 830mm x 830mm x 550mm, dual-laser architecture, and simplified user workflow, the SLA 825 Dual offers high-throughput SLA manufacturing for high-performance industries such as transportation and motorsports and aerospace and defense, as well as service bureaus. The SLA 825 Dual is engineered for long-term value and scalability – designed to be upgradeable for future technology innovations. The SLA 825 Dual is available for immediate ordering.

3D Systems

Sheet lasers

The LS7 sheet lasers are designed to improve accessibility and provide operators with greater ease of use. The LS7 3015 and 4020 models now feature a larger front access door and new access doors on both sides, along with a new ergonomic, adjustable operator control panel to ease programming. Both machines still offer up to 20kW laser capacity and 2g acceleration for fast, high-quality cuts and improved productivity.

The overall footprint on the LS7 has been reduced by 11%, making it suitable for smaller shops with limited floor space.

Active Sense is a new software feature improving cutting quality and increasing reliability through continuous process control when using nitrogen, air, or mixed gases.

As with the previous LS7 sheet lasers, the 3015 model handles a maximum sheet size of 121.5" x 62" and the 4020 handles sheet up to 162.5" x 79.5".

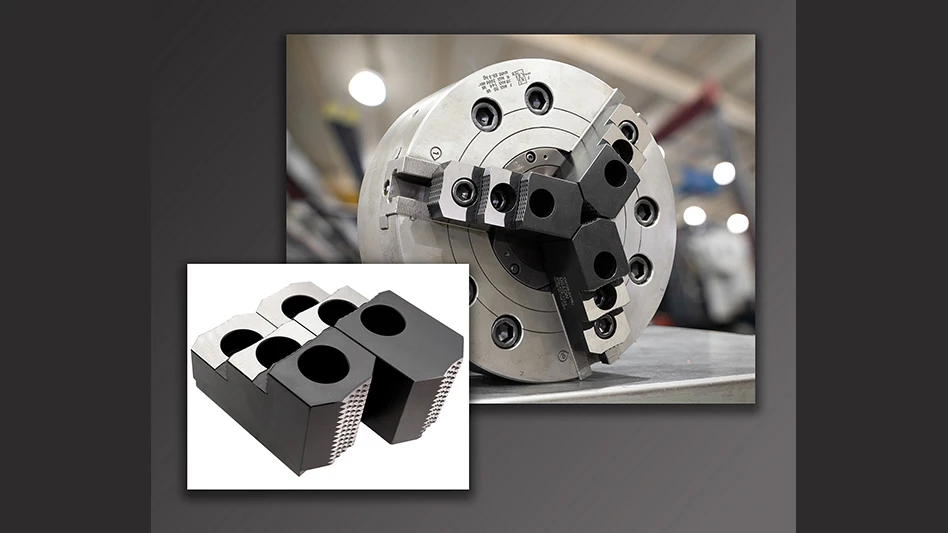

Cross hole deburring solutions of main bores

The SNAP-X line for cross hole deburring of main bores with multiple cross bores provides a reliable, automated solution reducing cycle time, improving consistency, and eliminating secondary operations. SNAP-X deburrs intersecting cross bores directly through the main bore in one pass. Different diameters and angles can be reliably processed within permissible tolerance range and verified feasibility. With two cutting edges working in both directions, it provides forward and backward cutting. A special guiding edge and gliding section prevent damage to the main bore during operation. Blades can be swapped by hand quickly and without tools, keeping downtime to a minimum. Each SNAP-X is custom-engineered and built for each customer’s specific application. SNAP-X is suited for high volume production runs requiring deburring main bores with multiple intersecting cross bores of different diameters and angles (up to nearly a 1:1 ratio).

HEULE Precision Tools

Explore the January/February 2026 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- HII places second Nikon SLM Solutions NXG 600E order

- L3Harris demonstrates interoperable network to unify Department of War and U.S. government agencies

- Platinum Tooling/Heimtec's speed increasers for lathes and Swiss-style machines

- U.S. Army awards Persistent Systems contract for $87.5 Million supporting Next-Generation Command and Control prototype

- Northrop Grumman successfully tests Mk 72 solid rocket motor for U.S. Navy

- Orqa announces Global Manufacturing Program to expand drone production to 1 million units annually

- Lantek's v.45 Suite software

- Kratos issues letter of intent for 60 full rate production Zeus hypersonic system rocket motors from L3Harris