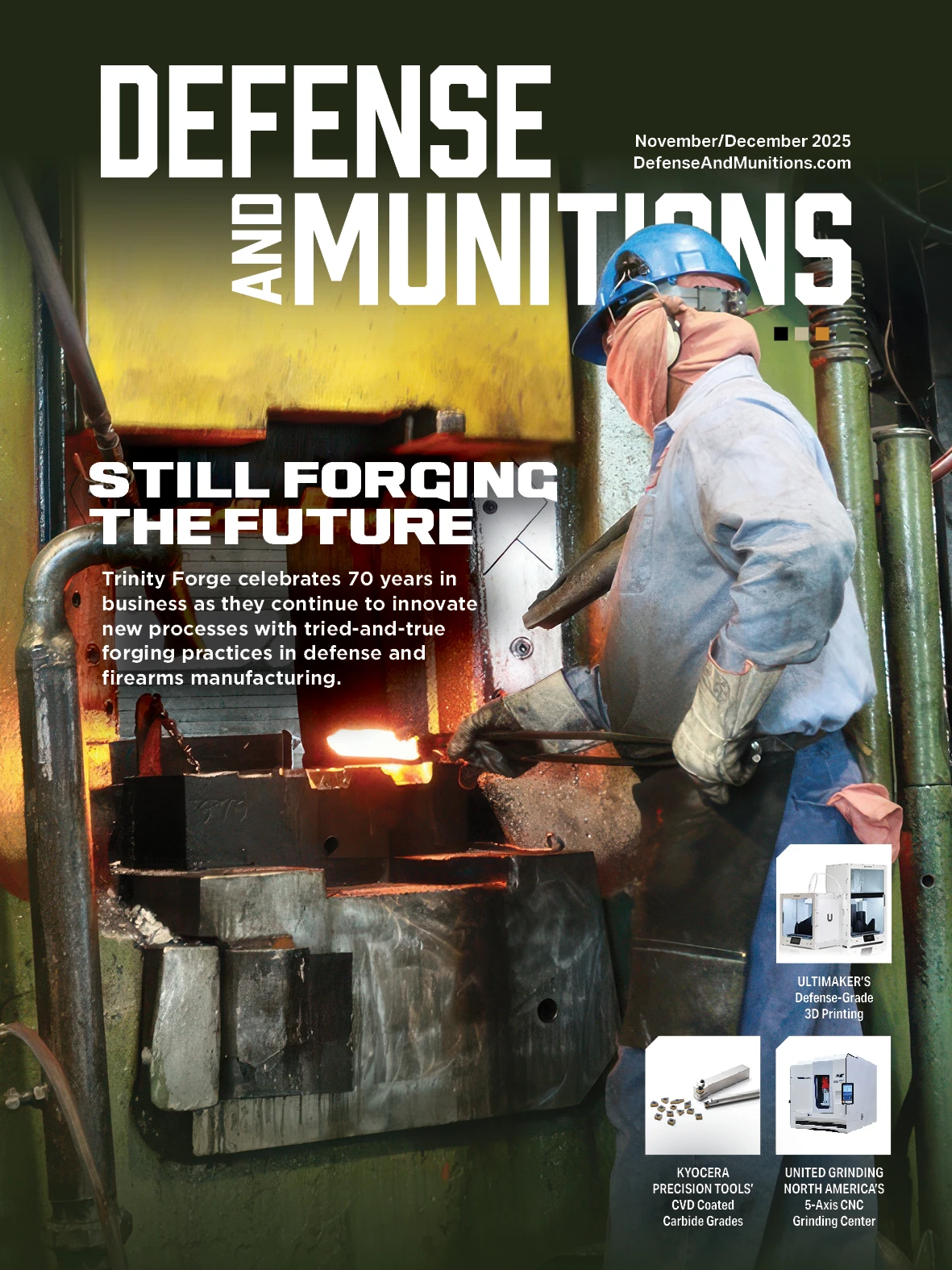

Forging is one of the oldest known forms of metalworking and Trinity Forge in Mansfield, Texas has been doing it since 1955. Times have changed in the manufacturing industry during those 70 years as multi-axis machining, additive manufacturing (AM), automation, robots, cobots, artificial intelligence (AI), and other emerging technologies have taken over many shop floors. Several of those technologies have worked their way into Trinity’s facility but many of the same practices are still in place from ’55.

“We still heat metal up, we still use brute force to shape metal as a blacksmith would,” says John Fairbanks, Trinity Forge CEO. “However, it’s a lot more technical and repeatable than what I saw 38 years ago or even 100 years ago, but it’s the same concept of heating metal and forming it with a grind flow to make a critical part, even if it was a sword made 200 years ago or a landing gear made for a Cessna aircraft today, we’re just smarter about doing it now.”

When Trinity was founded, the oil and gas industry made up approximately 80% of their business, but for a little more than a decade their focus diversified into defense, and currently the defense and firearms industry accounts for approximately 80%. The shift in focus also led to a shift in investment as Trinity needed to ensure their equipment was technologically advanced enough to pass government inspection and maintain defense contracts. Now Trinity continues forging while maintaining a CNC machine shop, a tool and die shop, and quality and engineering department. Fairbanks’ staff uses scanning software for quality control to get real-time feedback, reduce scrap, and make quality products.

“In our modern age right now, just look at all the technology we have access to in our personal lives, that has transitioned over to manufacturing,” Fairbanks says. “It’s made our jobs easier, not just making products easier, but having a more consistent repetitive process where every time you set up a job, you’re going to expect the same output of quality.”

Trinity currently employs approximately 115 people across two shifts. The majority of them began with no forging experience but now Fairbanks says his team averages 14-1/2 years of service. He credits the training they provide and the reskilling they maintain nearly every week. Every new employee goes through a week of orientation followed by observing on the shop floor, and Fairbanks knows training is key for younger workers coming in.

“You’re really over-hiring people to stage that next generation and keep turning people over, people retire so you have to always prepare,” Fairbanks says. “Engineering, quality, nondestructive testing, and maintenance positions, it takes years to skill someone up to have them prepared to take over.”

Fairbanks says Trinity is still just a job shop because they can make three parts or 30,000 parts, but automotive forges pump out 200,000 parts without changing anything over. On an average week, Trinity runs 20 different parts which means 20 different setups and 20 different routing systems across six different forging work centers, meaning robotics could be a tricky addition to the shop floor.

“Robotics is always something in my vision for Trinity or any forge shop but setups for robotics are very long,” Fairbanks says. “They’re really made to set this job up and run it for a week or two weeks where here I’m setting up a job in the morning, making the product, and then setting up a new job in the afternoon. My setups are more like 35 minutes versus a day for a robot. So, technology is coming along, I’m not ignoring it, but I’m not seeing it yet.”

Another emerging technology potentially seen as a rival to forging is 3D printing. Trinity actually 3D prints some of their dies for tooling and brings in outside metallurgy experts to help develop new materials for AM and find ways to incorporate those materials into the forging process.

“A lot of forgers will walk away from it, because it’s costly for the research side but our customers dictate what materials we use,” Fairbanks says. “I’ve seen many forge shops shut down due to that. Look to diversify not just your business, but also how you process your product.”

Fairbanks believes forging’s core strength lies in its ability to produce components with superior mechanical properties by refining the metal’s grain structure with the profile of the product. Key industries still heavily rely on forging for parts that cannot fail. Those products include general military aircraft munition, the lugs holding bombs to the plane, different types of guided munitions, breeches for artillery cannons, firearm frames, barrels, slides, gas blocks for machine guns, and more.

“We have equipment that can make parts in ounces up to 140 lb parts comfortably and we’re looking at even growing our forging capacity to double that to up to 300 lb parts,” Fairbanks says.

Fairbanks says forging is more attractive to the defense and firearms industry because its grain flow follows the profile of the product, adding ultimate strength to the part where a casting would be more like a kitchen sponge and 3D printing still has diffusion marks. Forging leaves you with a stronger, denser part with an improved grain structure.

Although forging may be one of the oldest forms of metalworking, it still has a firm footing in the manufacturing industry. And despite its long history, Fairbanks knows Trinity Forge will continue to innovate and respond to customers’ needs.

“When I started here, we had mechanical style hammers that were big gear-driven, they took a lot of operator skill to make a product, and not that it doesn’t take operator skill now, but you can control your heat and blow intensity to the forging with a computer,” Fairbanks says. “Trinity’s always invested into modernizing equipment, investing back into the company, the quality side, the people side, the engineering, getting different types of skill sets to improve our process. Without our customer base and without our employees, we’re not a company. The equipment will just sit so all the technology, everything we invest in, all that goes away without your people and your customers, so it’s pretty simple.”

Trinity Forge

https://trinityforge.com

A look inside Trinity Forge

TESTING AND QUALITY CONTROL EQUIPMENT

- Magnetic particle inspection

- Faro Quantum laser scan arm for 3D scanning

- Programmable & non-programmable CMMs

- Faro Gage Arms

- Laser and dot-peen Telesis machines

- Profilometers

IN-HOUSE DIE SHOP

- Vertical and horizontal CNC mills

- Boring machines

- Surface grinding equipment

- Radial drills

FORGING EQUIPMENT

- Lasco HOU 720 computer-controlled hydraulic hammer - 70 blows per min. | Max. part size 100 lb

- Lasco HOU 315 computer-controlled hydraulic hammer - 90 blows per min. | Max. part size 20 lb

- Lasco KH 125 computer-controlled hydraulic hammer - 60 blows per min. | Max. part size 8 lb

- Lasco KGK 250 computer-controlled hydraulic hammer - 60 blows per min. | Max. part size 20 lb

- Lasco HOU 400 computer-controlled hydraulic hammer - 90 blows per min. | Max. part size 35 lb

- Lasco HOU 800 computer-controlled hydraulic hammer - 70 blows per min. | Max. part size 160 lb

- Lasco KGK 160 computer-controlled hydraulic hammer - 60 blows per min. | Max. part size 12 lb

- Chambersburg #8 Die Forger computer-controlled hydraulic hammer - 90 blows per min. | Max. part size 8 lb

- Chambersburg 6,000 CECO drop forging hammer - 60 blows per min. | Max. part size 35 lb

- 24 trimming and pre-forming presses (58 tons to 500 tons)

- Automated, conveyor-fed induction heaters

- Standard induction heaters

- Billet sawing and shearing machines

- Water cooling systems

- Air compressors

- Roll machines

- Tumble shot blasting machines

- Vibratory media finisher

- Gas slot furnaces

MACHINING EQUIPMENT

- Mazak QT250 - 13.78" max. turn dia.; 20.2" max. length; 3" max. bar capacity; 1 unit installed

- Mazak QT350 26" - 16.5" max. turn dia.; 26.7" max. length; 4" max. bar capacity; 1 unit installed

- Mazak QT350 48" - 16.5" max. turn dia.; 49.1" max. length; 4" max. bar capacity; 1 unit installed

- Mazak QT450M - 23" max. turn dia.; 38.6" max. length; 6.5" max. bar capacity; 1 unit installed

- Mazak Integrex i400 - 25.91" max. turn dia.; 39.8" max. length; 4" max. bar capacity; 1 unit installed

- Mazak Integrex 3004S - 30" max. turn dia.; 60" max. length; 3" max. bar capacity; 1 unit installed

- Mazak HCN6000 - 19.69" Pallet; 4 units installed

- Mazak HCN4000 - 15.75" Pallet; 1 unit installed

- Mazak VTC 250/50D - 2 units installed

- Makino A99e - 2-ton table capacity; 31.5" Pallet; 1 unit installed

- Makino V77 - 2.5-ton table capacity; 1 unit installed

- Makino V56 - 1,760 lb table capacity; 1 unit installed

- Hyundai L300A - 19.7" max. turn dia.; 29.5" max. length; 3" max. bar capacity; 2 units installed

- Hyundai L300C - 22.1" max. turn dia.; 29.5" max. length; 3.5" max. bar capacity; 1 unit installed

SMALLEST ACHIEVABLE MACHINING TOLERANCES

- Linear tolerances: 0.0005"

- Geometric tolerances: 0.0005"

- Surface finish: 20√

ASSEMBLY AND FINISHING

- Welding

- Surface grinding

- Hardware affixing stations

Explore the November/December 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- US Navy selects L3Harris Red Wolf for Precision Attack Strike Munition program

- Snowbird Technologies integrates Meltio Engine Blue into containerized hybrid manufacturing system for defense

- Precision Additive's PA-300 LPBF 3D metal printer

- BIG DAISHOWA supports future of manufacturing with Tools for Schools program

- Mission-Ready: Hutchinson Aerospace & Industry achieves CMMC Level 2 certification

- Shotling's anti-drone shotgun

- ACMI breaks ground on first national manufacturing campus in Indiana, pioneering new model for American defense production

- December 2025 U.S. cutting tool shipments totaled $215M