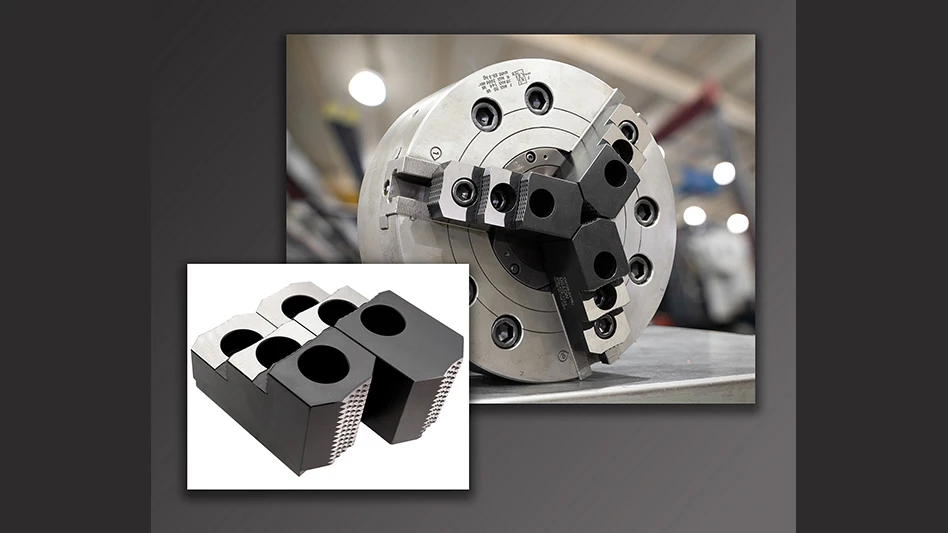

The TTS-85/125 is a high-performance multi-turret turning center for simultaneous machining for medium and high volume turning of large, long workpieces with up to four independent high-speed servo driven turrets made by Spinner. All turrets operate independently on the main or counter-spindle or can work on one spindle at the same time if desired.

Several configurations are available with optional steady rest to best meet specific part applications. A long bed option is also available, bringing 82.7" of work area between spindles. The TTS-85/125 machines typical large energy and oil parts quickly and easily.

The enlarged TTS-85/125 has a modular design and can be equipped with up to four turrets. The series is alternatively available with two powerful motor spindles up to 85mm or 125mm bar capacity. These motor spindles can be freely selected for the main or sub-spindles. This allows for high performance machining and large chuck machining up to approximately 500mm diameter, even simultaneously.

Flexible steady rests are possible, each optionally movable in two CNC axes on a cross-slide, to be brought quickly and precisely from protected park position to the usage position.

The robust servo indexing turrets are available with 12 or 16 positions. BMT45 or BMT65 tool holders are used for maximum changeover accuracy and cutting performance. There is also a choice of two bed lengths with normal and extended Z-stroke.

Explore the January/February 2026 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- HII places second Nikon SLM Solutions NXG 600E order

- L3Harris demonstrates interoperable network to unify Department of War and U.S. government agencies

- Platinum Tooling/Heimtec's speed increasers for lathes and Swiss-style machines

- U.S. Army awards Persistent Systems contract for $87.5 Million supporting Next-Generation Command and Control prototype

- Northrop Grumman successfully tests Mk 72 solid rocket motor for U.S. Navy

- Orqa announces Global Manufacturing Program to expand drone production to 1 million units annually

- Lantek's v.45 Suite software

- Kratos issues letter of intent for 60 full rate production Zeus hypersonic system rocket motors from L3Harris