Redacted Industries LLC

Additively manufactured firearms have been termed “ghost guns” because of how hard it is to trace a 3D-printed gun with schematics to print them found in the deepest, darkest recesses of the internet. That’s where Nick Donarski lived for years as he worked cybersecurity for state, national, military, and Fortune 10 entities. He picked up an interest in 3D printing to make little microprocessors and other tech gadgets before he started printing his own firearms about 10 years ago.

Donarski doesn’t consider himself a “gun nut”; he does hunt and goes shooting with his family, but his shop is filled with tools and machines, not lined with firearms on the walls. However, his breakthrough could cause major disruption in the firearm industry.

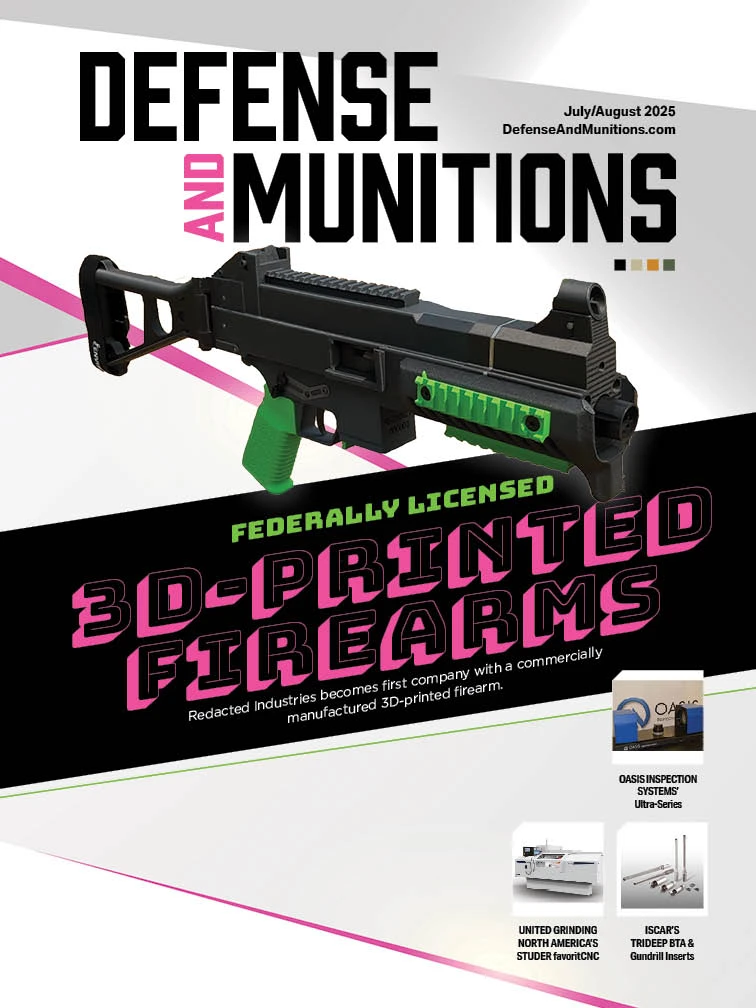

Redacted Industries LLC, a company founded by Donarski, earlier this year became the first federally licensed manufacturer in the United States to commercially produce and distribute serialized 3D-printed firearms as they were granted a Type 07 Federal Firearms License (FFL) and Class 2 Special Occupational Taxpayer (SOT).

Using composite PAHT carbon fiber for most load bearing parts and composite PPA carbon fiber for heat related parts, Redacted Industries was able to print the RI 9MP and the RI 9KMP.

“All of our analysis, all of our algorithms have been done, taken all of my nerd experience of the last 30 years, we’ve gone through research and development, breaking guns, blowing things up, leveraging SolidWorks to do all the CAD design for the dynamics and gas expansion beforehand,” Donarksi says. “Then we actually take that over to our printers and we’re able to produce with high detail and the cost of entry isn’t hundreds of thousands of dollars like it used to be, we’re running on three printers right now and the printer investment cost has been less than $3,000.”

However, getting federally licensed hasn’t kickstarted a printing empire yet for Redacted Industries. They haven’t been able to advertise their services on social media because 3D-printed firearms are actually against their terms of service. The RI 9MP and RI 9KMP have been embraced by the firearms community when Donarski displays them at gun stores and gun shows. The firearms are customizable with 27 different colors available, along with other options and accessories which Redacted Industries also manufactures. Initial plans were broader for Redacted Industries, but Donarski scaled back for good reason.

“When I started this in the startup mentality, I was going to try to launch this with four pistol lines and two mid-size and then I realized whoa, slow down,” Donarski says. “We’re not going to try to spread ourselves too thin on this. Let’s do the smart thing, let’s focus on a single line, let’s do it right. And then once we get that part and get that adoption, people aren’t scared of 3D-printed firearms, it becomes normalized.”

Redacted Industries exclusively uses QIDI Plus 4 printers and PAHT-CF materials with Siraya Tech PPA materials and PolyLite ASA materials. QIDI PAHT-CF combines a high-temperature nylon base with 15% chopped carbon fiber reinforcement, creating a filament that doesn’t flinch under recoil or high-cycle abuse, so it’s used on firearm frames, uppers, slide interfaces, and magwells. Siraya Tech PPA is used for barrel block assemblies, front-end heat zones, and suppressor-facing structures because it possesses high-heat containment and thermal stability near muzzle pressure zones. The ASA materials bring color depth and pigment stability for grips, safeties, mag releases, brace buttons, and external panels.

After 14 months of research and development along with design and testing, Redacted can now print a complete firearm in three days. Currently Redacted is focused on customizable firearms for civilians but looking to expand into full-on retail. Donarski is in discussions to get the RI 9MP and RI 9KMP on shelves of local and regional firearms retailers in Iowa. With the current uncertainty with tariffs, Redacted has also been in conversations with other firearms manufacturers outside the U.S. looking for component manufacturers on U.S. soil to produce grips, accessories, and other small parts instead of shipping them from overseas.

The RI 9MP and RI 9KMP are qualified for law enforcement use but are not cleared for military use by the DOD or NATO, but Donarski hopes to change that one day.

Donarski wants to stress that the RI 9MP and RI 9KMP are not cheaper options when it comes to firearms. The designs don’t feature a lot of extra hardware so the average firearm user can strip them down and put them back together, but the firearms must hold up to traditionally machined or forged firearms.

“There’s no skimping because if we did, the first one that breaks means every other one doesn’t matter,” Donarski says. “It doesn’t matter how many we’ve done right because we’re the first and because there’s already kind of a hesitation when you say 3D printed; if it breaks under normal circumstances, that’s the end.”

There’s no skimping when it comes to keeping records either, as Donarski was told during Redacted’s Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) inspection; the majority of fines handed out by the ATF are due to errors in logging. That’s where Donarski, a self-professed “data nerd”, was able to use his tech background to develop software to track every step of the manufacturing process for his firearms. He has plans to further the tracking abilities once the firearm is sold.

“We talk about the future of manufacturing, the next step is integrating Near Field Communication (NFC) tags into our firearms to allow us to embed our serial numbers with a goal for developing software to track from manufacturer to sale or disposal and then building a mobile app for law enforcement to do their searches,” Donarski says.

The federal license allows Redacted Industries a lot of freedom when it comes to expanding their printing of firearms in the future, outside of printing a firearm that qualifies as a machine gun. When speaking of the future, Donarski believes 3D printing will help bring manufacturing back to America.

“Manufacturing will never come back to the United States like it used to be, it’s not going to be forges that come back, it’s not going to be these massive machining plants and manufacturing plants of the ’60s, it’s going to be industrial buildings full of 3D printers and CNCs,” Donarski says. “The future of firearms isn’t forged, it’s printed.”

“The future of firearms isn’t forged, it’s printed.”

Redacted Industries LCC

https://redactedinnovation.com

Explore the July/August 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- AV delivers JLTV-mounted LOCUST Laser Weapon Systems to U.S. Army

- James Tool Machine & Engineering, Inc. maintains As9100 Certification

- Sunnen Products Company's PGA-1000 Air Gage

- Xact Metal names Mark Barfoot VP – Global Sales

- REGO-FIX appoints Joshua Burnett Midwest Territory Sales Manager

- Accutek and Diebold's PTI63 (CAPTO C6) and PSC63 (CAPTO C6) shrink-fit holders

- Mazak Ez machines showcase affordable performance at Expo Manufactura 2026

- New Mazak Phoenix Technical Center opens for business