Editor's Note: This article originally appeared in the January/February 2026 print edition of Defense and Munitions under the headline “Advancing military capabilities.”

A Leaders from the 278th Armored Cavalry Regiment (ACR) and Field Maintenance Shop-2 (FMS-2) of the Tennessee Army National Guard (TNARNG) and the DEVCOM Army Research Laboratory (ARL) recently joined researchers from University of Tennessee (UT) at the Knoxville Armory for a demonstration of cold spray expeditionary manufacturing capabilities. The project could help solve supply chain issues in the U.S. military and will support a directive from the Secretary of War to extend advanced manufacturing and additive manufacturing (AM) efforts to operational Army units by 2026.

UT researchers have worked with DEVCOM ARL for the last five years to build advanced manufacturing capabilities supporting military operations in the field. Army funding supports applied research and investment in new technology advancing warfighter readiness. It allowed the UT team to purchase an expeditionary manufacturing 3D printer to build Army-relevant parts using metal powder in a process called cold spray additive manufacturing. The partnership with the TNARNG allowed the team to embed the printer in the Knoxville Armory near UT’s campus for the demo.

“The Tennessee Army National Guard, working with UT, is the first unit in the Army to place this ruggedized mobile additive manufacturing capability within an operational unit,” says Bruce LaMattina, executive director for defense and special programs in the Tickle College of Engineering. “This system can produce critical replacement parts that would otherwise take months to procure, enabling rapid repair of Army vehicles closer to the battlefield. This capability keeps units mission-ready and helps get soldiers out of harm’s way.”

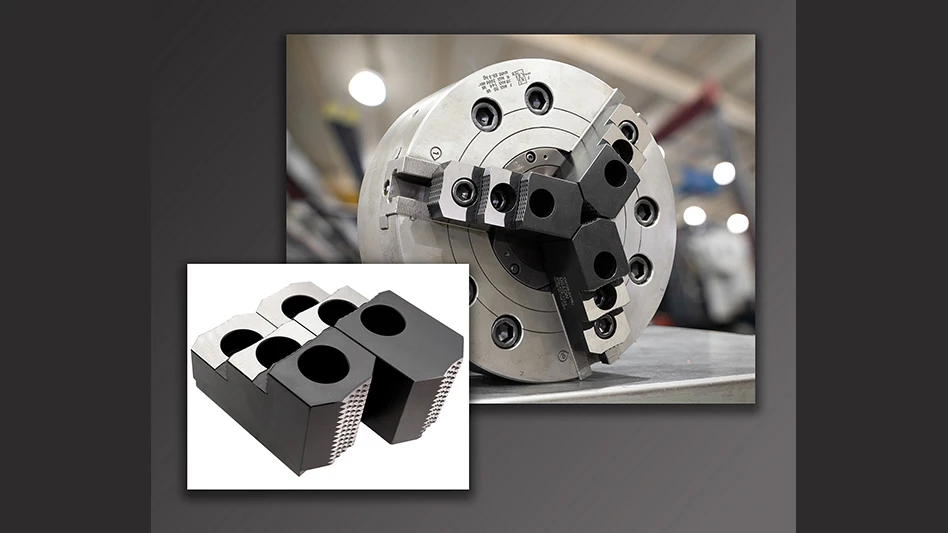

The leadership team also observed the heat treatment and machining processes developed by SPEE3D, a global supplier of metal AM technology, and UT researchers enabling finishing and installation of the 3D-printed machine parts and lithium-ion drone packs.

“We excel in metallurgy, advanced materials, materials processing, and material characterization,” says Katherine Page, professor of materials science and engineering at UT and a leader of the research team. “The cold spray technology is an emerging area of research for us and builds on our proven experience combining manufacturing and machining with materials science.”

UT researchers in the ARL project are also working on a “commander’s playbook” to understand the trade-offs between processing time and part performance with a high level of confidence. “Although developing the commander’s playbook requires a high level of sophisticated research, the outcome will provide commanders in the field with actionable information to determine what is ‘good enough’ for mission success under specific operational conditions,” Page says.

Many aspects of this work involve UT students, from undergraduates to postdoctoral researchers, who benefit as scholars and as future members of the workforce.

“After spending the summer at the Army Research Lab, I came back to UT with a much deeper understanding of how this technology can make a real impact,” says Hunter Lambert, a third-year graduate student who spent his summer embedded with ARL at Aberdeen Proving Grounds, a U.S. Army facility in Maryland. “Once we began printing parts – like a locking door handle for a mine-resistant ambush-protected vehicle – it hit me that this work isn’t just about materials, it’s about keeping our service members safe.”

The University of Tennessee — Tickle College of Engineering

Explore the January/February 2026 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- HII places second Nikon SLM Solutions NXG 600E order

- L3Harris demonstrates interoperable network to unify Department of War and U.S. government agencies

- Platinum Tooling/Heimtec's speed increasers for lathes and Swiss-style machines

- U.S. Army awards Persistent Systems contract for $87.5 Million supporting Next-Generation Command and Control prototype

- Northrop Grumman successfully tests Mk 72 solid rocket motor for U.S. Navy

- Orqa announces Global Manufacturing Program to expand drone production to 1 million units annually

- Lantek's v.45 Suite software

- Kratos issues letter of intent for 60 full rate production Zeus hypersonic system rocket motors from L3Harris