The U.S. Navy’s shipbuilding momentum recently received a $5 billion boost. The Defense Logistics Agency (DLA) Maritime Mechanicsburg awarded a Maritime Acquisition Advancement Contract (MAAC) to six small businesses to fast-track support for submarines and active surface ships. With the potential to double to $10 billion over five years, this investment underscores the urgency to equip shipyards with faster, safer, and more precise fabrication capabilities. One solution increasingly gaining traction is plasma cutting. In addition to being ideal technology for addressing a wide range of materials, hull shapes, and performance needs, plasma is a process helping shipbuilders meet tightening timelines and stringent quality standards while improving worker safety and operational efficiency.

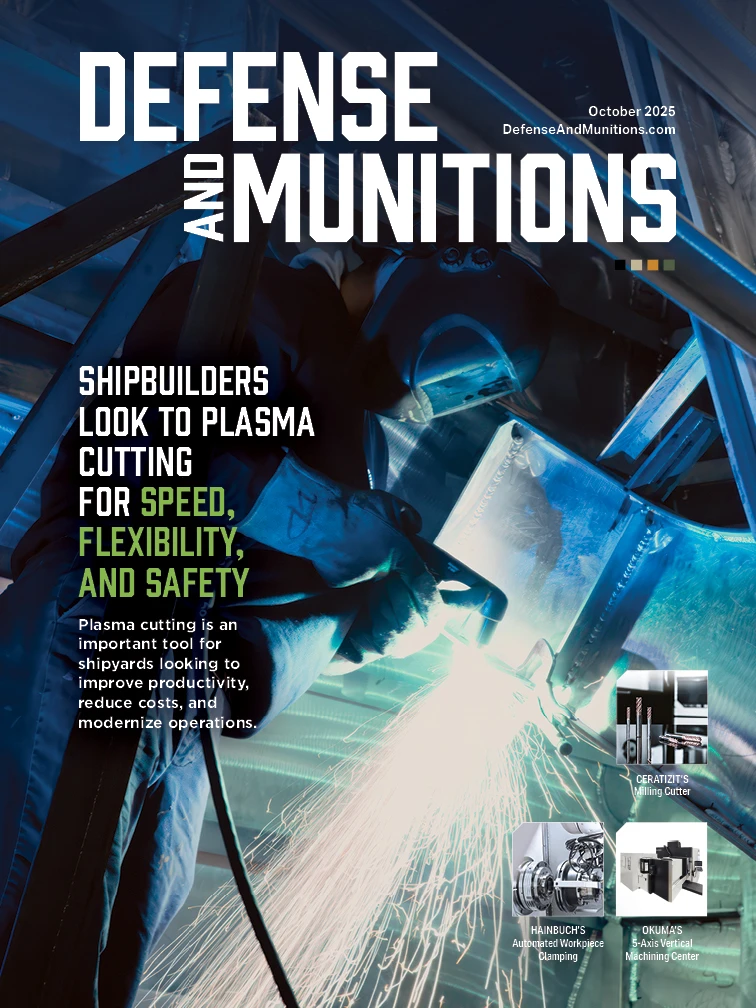

Traditionally, shipyards have relied on oxyacetylene, especially for thick mild steel and carbon-arc gouging. The growing shift toward aluminum and stainless steel, neither of which can be cut with oxyfuel, for corrosion resistance, fuel efficiency, and advanced naval stealth capabilities, requires alternative cutting and gouging methods. Once seen as a supplementary technology, plasma cutting is an important tool for shipyards looking to improve productivity, reduce costs, and modernize their operations.

Adapting to new demands: Why materials are changing in shipbuilding

Though steel remains a pillar in the shipbuilding industry, new ship designs are increasingly incorporating aluminum and stainless steel – especially in high-performance and specialty vessels.

- Aluminum is lightweight, boosting fuel efficiency and vessel speed.

- Stainless steel resists corrosion, essential for components exposed to saltwater.

- Titanium and other advanced alloys provide mission critical advantages for defense agencies.

This increase in material diversity is driving the need for a more versatile cutting system that doesn’t force shipyard workers to switch between multiple machines or processes as they encounter different materials. Plasma systems can be used for a variety of handheld, mechanized, and robotic cutting and gouging applications on a range of metal types and thicknesses. For instance, operators can use a hand torch to cut away temporary attachments and to gouge out a defective weld or use a machine torch mounted in a tractor to back gouge for weld preparation.

Plasma cutting: The process

Plasma cutting is a versatile process using a compressed jet of ionized gas or plasma to cut through metals. The plasma stream is usually formed by forcing gases such as nitrogen, oxygen, argon, or air through a narrow nozzle. The gas stream is then ionized using an external power supply, creating a plasma arc cutting the workpiece by first melting it and then blowing it away.

Plasma cutting can work with most electrically conductive metals, including ferrous metals such as carbon steel, cast iron, and stainless steel. It can also cut non-ferrous metals such as aluminum, brass, and copper. Plasma cutting is typically used for metals up to 2" thick, although high amperage models can cut up to 6". The technology causes little to no metal deformation. Because plasma cuts fast with little slag or dross, plasma torches produce more accurate cuts with a smaller kerf than oxyfuel torches.

Making shipyards safer while doing more with fewer workers

Shipbuilders are under constant pressure to do more with fewer hands. The skilled labor shortage is especially pronounced in this industry, where expertise in layout, fitting, and welding takes years to develop. Recruiting and retaining talent is made even harder by the very real hazards found in traditional cutting methods. The fumes generated by oxyfuel and carbon-arc systems, for example, put workers at risk of fire, burns, and respiratory hazards. Ergonomic stress and repetitive strain from manual grinding and cutting operations can lead to chronic, long-term injuries, and the complex training requirements to implement these systems delay onboarding and limit flexibility on the production floor.

Plasma cutting technology directly mitigates threat of injury by offering a safer, cleaner, quieter, and more intuitive cutting solution. Workers aren’t exposed to combustible gases or extremely noisy applications, fumes are often reduced, and plasma cut and gouge quality can minimize the risk of strain or injury from excessive grinding.

Benefits for the bottom line

Plasma cutting benefits reach beyond safety and versatility to cut multiple materials and workpiece thicknesses. Plasma systems deliver measurable results for shipbuilders’ bottom line.

To start, plasma cutting is up to 70% faster than traditional cutting methods, and shipbuilders using plasma in their operations see faster returns on their investment as improved cut quality and tolerances reduce the need for grinding. Faster cycle times enable higher throughput even with fewer workers. Cleaner, safer work environments improve recruitment and retention, and reduced material handling and space requirements optimize shipyards’ square footage.

With a sophisticated, easy-to-use technology such as plasma, production managers find downstream cost savings as well. Advanced features such as Hypertherm Powermax SYNC cartridge technology adjusts amperage and process settings and simplifies consumable changeouts, reducing reliance on skilled operators. A single-piece consumable cartridge design streamlines consumable replacement with a pre-assembled, self-contained unit containing the elements found in a traditional stack. The cartridge can be replaced with a simple quarter-turn, allowing even inexperienced operators to avoid mistakes in assembling the traditional 5-piece stack-up and cut effectively with minimal downtime lost to changeovers.

Cobot capable

With large-scale operations required in many shipbuilding applications, the industry may never be fully automated. Cobot plasma cutting and gouging offers an efficient middle ground between human labor and full automation.

Integrating plasma systems with cobot technology enables shipyards to relieve skilled operators of repetitive tasks, perform 3D cuts in hard-to-reach areas, increase accuracy and consistency on complex jobs, and reduce physical strain on workers. For plasma cutting systems designed for easy cobot integration, the barrier to entry is low, with little custom development or complicated retrofitting required.

Cutting lead times, accelerating production

The recent MAAC contract awards highlight a growing commitment to address acquisition and supply chain issues for faster, more efficient defense maritime production. To keep pace with the dynamic needs of the industry, shipbuilders must adopt versatile and cost-effective technology and processes while keeping workers safe and maintaining stringent quality standards. Plasma cutting technology is a high-performance alternative to traditional cutting methods giving shipbuilders the ability to do more with less – less labor, less waste, and less downtime.

Hypertherm Inc.

https://www.hypertherm.com

Explore the October 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- Xact Metal names Mark Barfoot VP – Global Sales

- REGO-FIX appoints Joshua Burnett Midwest Territory Sales Manager

- Accutek and Diebold's PTI63 (CAPTO C6) and PSC63 (CAPTO C6) shrink-fit holders

- Mazak Ez machines showcase affordable performance at Expo Manufactura 2026

- New Mazak Phoenix Technical Center opens for business

- Guill Tool's Unicam extrusion crosshead

- Hypertherm Associates invites North American schools to apply for Spark Something Great education grant

- PteroDynamics, AV demonstrate integrated EW capabilities on Transwing VTOL UAS at U.S. Navy Silent Swarm 25 Exercise