The current U.S. shipbuilding industry is hurting as some submarine and warship manufacturing programs are as far as three years behind schedule. Military Times reports the U.S. Navy wants to grow its fleet from 295 ships to 381; however, they also plan to retire as many as 13 ships by 2027. Building new ships and submarines isn’t the only problem; maintaining the current fleet is tricky since nearly 40% of all Navy submarines await maintenance but currently don’t receive it due to lack of capacity at shipyards according to Risk Mitigation Consulting. So, what’s the solution? More shipyards could be developed, even more of a concentrated effort could be made to increase the workforce, more government funding could allow for the purchase of more materials needed in the shipbuilding process, or the current shipyards could be run more efficiently.

The vast majority of shipyards use very antiquated processes and outdated technology because until recently there hasn’t been a massive focus on shipbuilding since the Cold War.

The U.S. Naval Institute previously reported since 2018, America has invested more than $2.3 billion into the submarine and maritime industrial bases; however, only $174 million of that was directly for technological innovation. There’s also $29 billion in the “One Big Beautiful Bill Act” allocated to revive the country’s shipbuilding and maritime industrial base.

Adaptiv AI hopes to help make current shipyards more efficient. Ivan Madera, the founder and CEO of Adaptiv AI, has spent the past 25 years in advanced manufacturing, including the past 10 years in 3D printing, so he knows advanced manufacturing technologies can’t be looked at as separate islands but can all be incorporated into a seamless process.

“There’s different design intent, there’s a lot of things that you can do now that, quite frankly, you couldn’t do 20 plus years ago,” Madera says. “It was much simpler, the vehicle classes were simpler, the technology was simpler, you couple it today with a level of complexity and the skilled labor, I think labor’s really the driving force behind a lot of this.”

Madera wants to create an environment where there’s a level of flexibility to build different classes of vehicles and munitions whether through robotics, large format directed energy deposition (DED), robotic laser deposition, wire-arc directed energy deposition, or engineering. He believes there are large scale components that can be consolidated, and artificial intelligence (AI) can be used to speed up consolidation.

“You’re basically creating this near net shape structure, it’s pretty raw, in kind of a natural state, requiring a good level of inspection, so there’s tool path, inspection, and then post machining. You can do DED, that takes five days, then inspect it, then machine it, now you’re talking 10 days plus just for one large structure. We can bring AI to the fold, machine learning, to basically view a part as it’s being built, which shrinks and kind of distorts, and know where you’re at in space 100% of the time, visually seeing what you’re doing and how you’re depositing, adjusting tool path based on what it sees, repairing based on what it sees, but also machining. And that’s really where, when we look at the shipbuilding process or larger format things, you can take advantage of AI.”

On the operational side, Madera believes AI can help alleviate any problems that pop up when there’s a supply chain disruption. AI can be used to reschedule or retool based on available materials and manpower by looking at suppliers, the factory floor, and available materials to determine what can be produced and then later when supplies come in, the processes can converge simultaneously instead of waiting for analysis. It’s an adaptive process, which leads to the naming of the company.

Adaptiv AI can help shipyards design factories to be flexible by providing planning, scheduling, quality, and engineering systems that are then maintained by the contractors moving forward. Madera’s team can train, educate, and augment new and incoming workforce at government-owned, contractor-operated shipyards (Go-Co’s) but knows there’s a transient workforce when it comes to government-owned, government-operated shipyards (Go-Go’s) since military personnel may only be deployed there for a short time. Adaptiv AI can help integrate automation and then use an experienced military personnel’s history to augment and develop a machine learning program to allow new military personnel to learn the process on demand.

Madera has seen some reluctance to change current processes in shipyards because while the technology could be new, the paperwork will still be outdated.

“Let’s say you’re going to use DED; the documentation is still for casting or forging,” Madera says. “Until a lot of this underlying paperwork and engineering drawings and things of that nature get updated, it’s going to be quite challenging to kind of move the needle. I think there’s a level of intrigue, and then it’s a matter of someone having to make a decision, let’s go spend $100 million to modernize the factory. And the money’s there. And the appropriation bill, if you look line by line, there’s tons of money for modernization or advanced manufacturing or AI.”

Madera believes the best place to start in modernizing shipyards, or any manufacturing facility, is the quality processes because it’s a data-rich environment with standards and documentation, along with good and bad outcomes to track and analyze. That analysis helps turn advanced manufacturing technologies into easy-to-understand and easy-to-integrate plans of operation.

“What if you can augment the workforce, automate some of these processes to be able to bring in unskilled labor to run a second shift or third shift?” Madera says. “What if we could leverage the data that already exists and use AI to help take the guy flipping your burger yesterday, and tomorrow he’s machining parts?”

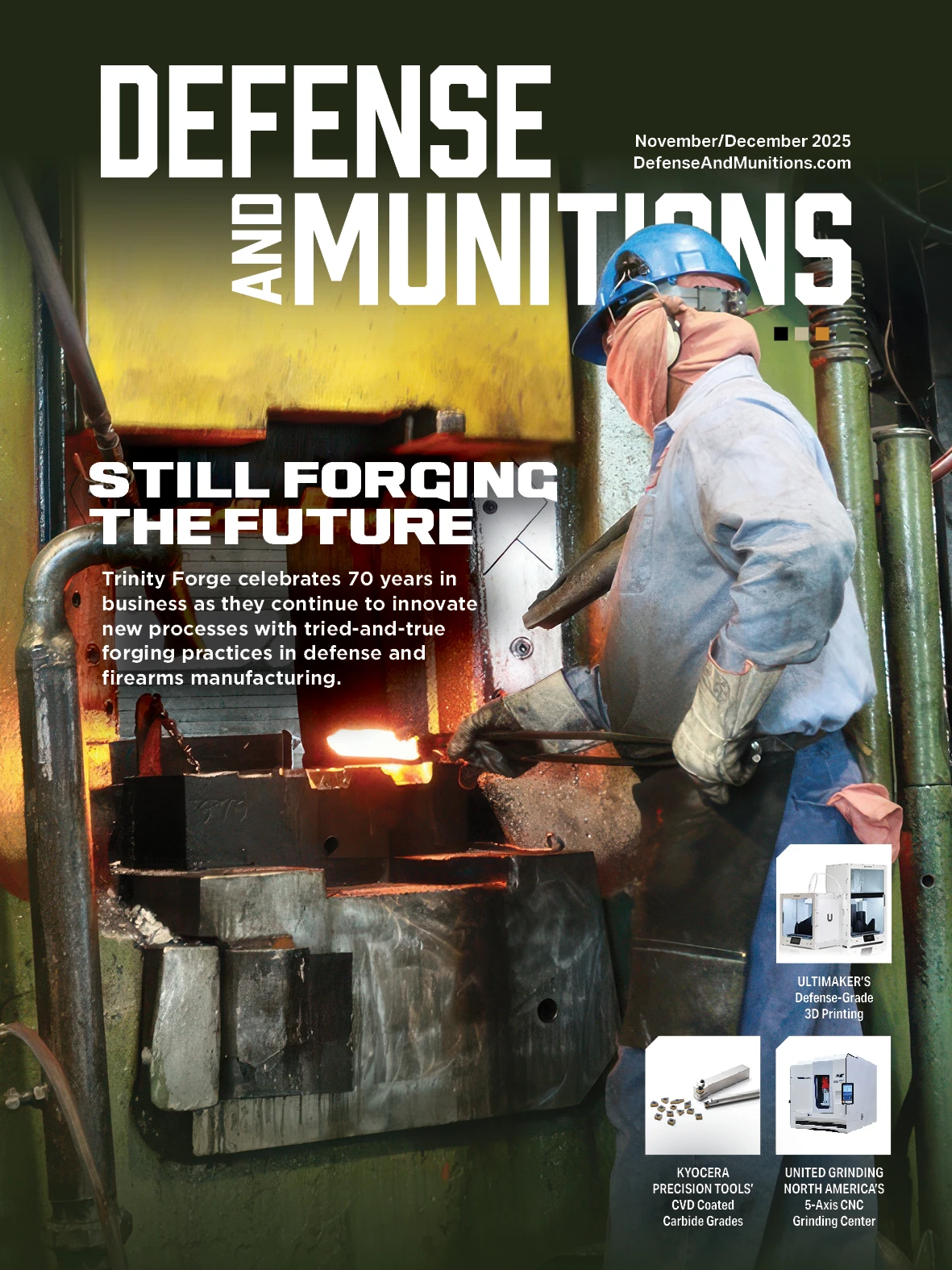

Explore the November/December 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- US Navy selects L3Harris Red Wolf for Precision Attack Strike Munition program

- Snowbird Technologies integrates Meltio Engine Blue into containerized hybrid manufacturing system for defense

- Precision Additive's PA-300 LPBF 3D metal printer

- BIG DAISHOWA supports future of manufacturing with Tools for Schools program

- Mission-Ready: Hutchinson Aerospace & Industry achieves CMMC Level 2 certification

- Shotling's anti-drone shotgun

- ACMI breaks ground on first national manufacturing campus in Indiana, pioneering new model for American defense production

- December 2025 U.S. cutting tool shipments totaled $215M