Since 1927, the Lawton family and Star Cutter Co. have been manufacturing in Michigan and continue to expand and diversify their portfolio while maintaining supply lines in the United States, ensuring a quality American-made product. Whether it’s their H.B. Carbide division, which we covered in our August issue of Defense and Munitions magazine, their Grinding Technologies division, which we covered in our September issue, or their Deep Hole Drilling Operations, which we’ll focus on today, Star Cutter Co. continues to serve the defense and firearms industry.

Internal beginnings

Star Cutter Co.’s Deep Hole Drilling Operations began in 1955 when they first started manufacturing pressure reamers and expanded in 1958 when they manufactured their first gundrill. These products, like many others in the Star Cutter Co. family, were used in house first before being introduced to customers. Further expansion of their operations came in 1972 when they opened a dedicated facility for their Deep Hole Drilling Operations in Ossineke, Michigan.

Now the approximately 33,000ft2 facility produces ISO 9001 certified single-flute gun drills, solid carbide single-flute gun drills, double jet gun drills, double crimped gun drills, two flute-two hole gun drills, custom solid carbide gun drills, push and pull reamers, and rifle buttons. While employing 42 people, they also maintain an engineering and design team that works hand-in-hand with the facility’s tech supervisor to design tools for their customers. The implementation of an increasing amount of automation at this facility has led to the adoption of additional automation at all the other Star Cutter facilities.

“Ossineke has been the driving force in adoption of automation within Star Cutter, and we’ve been very successful with that over the last approximately five years,” says Corey Morrison, plant manager for Star Cutter Co.’s Deep Hole Drilling Operations. “The investments in technologies ultimately lead to a better tool including more uniform cutting, enhanced tool life for our customers, better coating adhesion, and resistance to micro defects.”

True vertical integration

The Deep Hole Drilling Operations receive carbide from H.B. Carbide and use Star Grinding Technologies machines to manufacture their gundrills, reamers, and buttons. Cross-functional internal teams from the other divisions of Star Cutter Co. meet regularly to discuss operations and troubleshoot any potential problems that could affect customers.

“I think our swim lane is much wider because of our capabilities and our applications support,” says Chris Cella, Star Cutter Co. applications engineering and account manager. “It’s much wider than a lot of our competition because we have that transfer of information from the field right back to the factory. Our team makes exceeding our customers’ expectation the norm, making our custom tooling go far beyond the standards we see our competition is putting out there so we have an advantage to push the boundaries.”

Diversifying the shop floor

The Deep Hole Drilling Operations shop floor is divided into sections for steel, carbide, and product integration since they can make products out of steel, solid carbide, or, in the vast majority, with steel AND carbide features.

On the metal side, Deep Hole Drilling Operations maintains a rolling inventory with thin tubing primarily for single flute gundrills, thick wall tubing primarily for pull reamers and buttons, solid tubing for two-flute products, and various other sizes depending on customer needs. Shanks are milled while drills are crimped, heat treated, straightened, and finished. From there, the drills are cut to length, and a V is ground into the end to set up for a carbide head to be brazed onto it.

On the carbide side of the floor, carbide parts start on an outside diameter grinder with robotic load and unload to allow Deep Hole Drilling Operations to run lights out when needed. Carbide parts are polished by a cobot, ground to size using a grinder, then flutes or contours will be ground into the carbide tools if needed.

The carbide tips are brazed onto the drill bodies, then cleaned and flow tested before the tool goes to the final straightening process and one last inspection before they are shipped to the customers.

Listening to customers

The customers’ specifications vary but Deep Hole Drilling Operations always works with customers on their designs and offers suggestions on what could work best.

“There are scenarios where one suggestion goes on to become a part of our products, with our applications engineers sometimes being the ones bringing back ideas to the plant, or myself, and then we implement it,” says Rick Rickert, product manager - round tools for Star Cutter Co. “We have such great relationships with our customers that we can collaborate with them, and they give us opportunities to develop new solutions based on these field discoveries.”

That process has led to Deep Hole Drilling Operations developing a barrel reamer design that extends tool life 10x to 20x per reamer. Previous designs weren’t very stable and even tools within the same manufacturing lot would give customers a completely different performance. The design and engineering team along with applications engineers were able to develop a stable tool that would consistently manufacture good parts.

“When the tool is not stable, you get a bad part, you get a bad finish on the barrel, inner diameter, and then that bad finish won’t go away, even after the rifling operation, so the barrels would have to be scrapped,” Cella says. “So, what we’ve done with our most recent design is stabilized that barrel reaming process so much so that we’re seeing 10 to 20 times the tool life. A lot of these manufacturing cells at the end user are fully automated so this tool can run at one end of the spectrum or the other so they can perfectly balance and time out the rest of their operation, not have this big bottleneck. It’s just proven to be a wonderful design. We couldn’t have even dreamed of a tool like this without the close collaboration of our customers.”

Filling customers’ needs quickly

The company also houses an Express In-Stock Drill program where customers can order gundrills from a stock of pre-hardened lengths and diameters with a standardized shank. Morrison and his team can quickly cut the drills to the customer’s size, braze a carbide head onto the top of the drill, and ship the parts out to customers in 10 days or less. Customers can order up to 25 parts of a specific diameter and length before having to go to Star Cutter’s standard product offering and lead times. The Express program is restocked almost daily to meet the customers’ needs quickly.

Deep Hole Drilling Operations offers a tool reconditioning and resharpening program as well where customers can ship used tools back to the Ossineke facility where the tools will be re-brazed with new carbide heads then sent back to the customers.

“When we resharpen, we go through the process of re-straightening, this including multiple quality checks and balances to ensure the tool is returned to like new condition,” Rickert says. “The customers that have used it know the value behind it. When you push the limit, that’s where you run into the issues, you’re not going to get the life that you expect out of it.”

Deep Hole Drilling Operations supplies some of the largest firearms manufacturers in the world and also smaller custom boutique firearms and barrel manufacturers. Regardless of the size of the customer, the relationship with Star Cutter Co.’s Deep Hole Drilling Operations doesn’t end when the part is sold.

“The icing on the cake is, after walking through that entire process, the homegrown support of our application engineering team that goes out there, troubleshoots, and has the ability to then perfect the customer’s manufacturing process based on the performance in the field, and ending with a better customer product,” Cella says.

Star Cutter Co.

https://starcutter.com

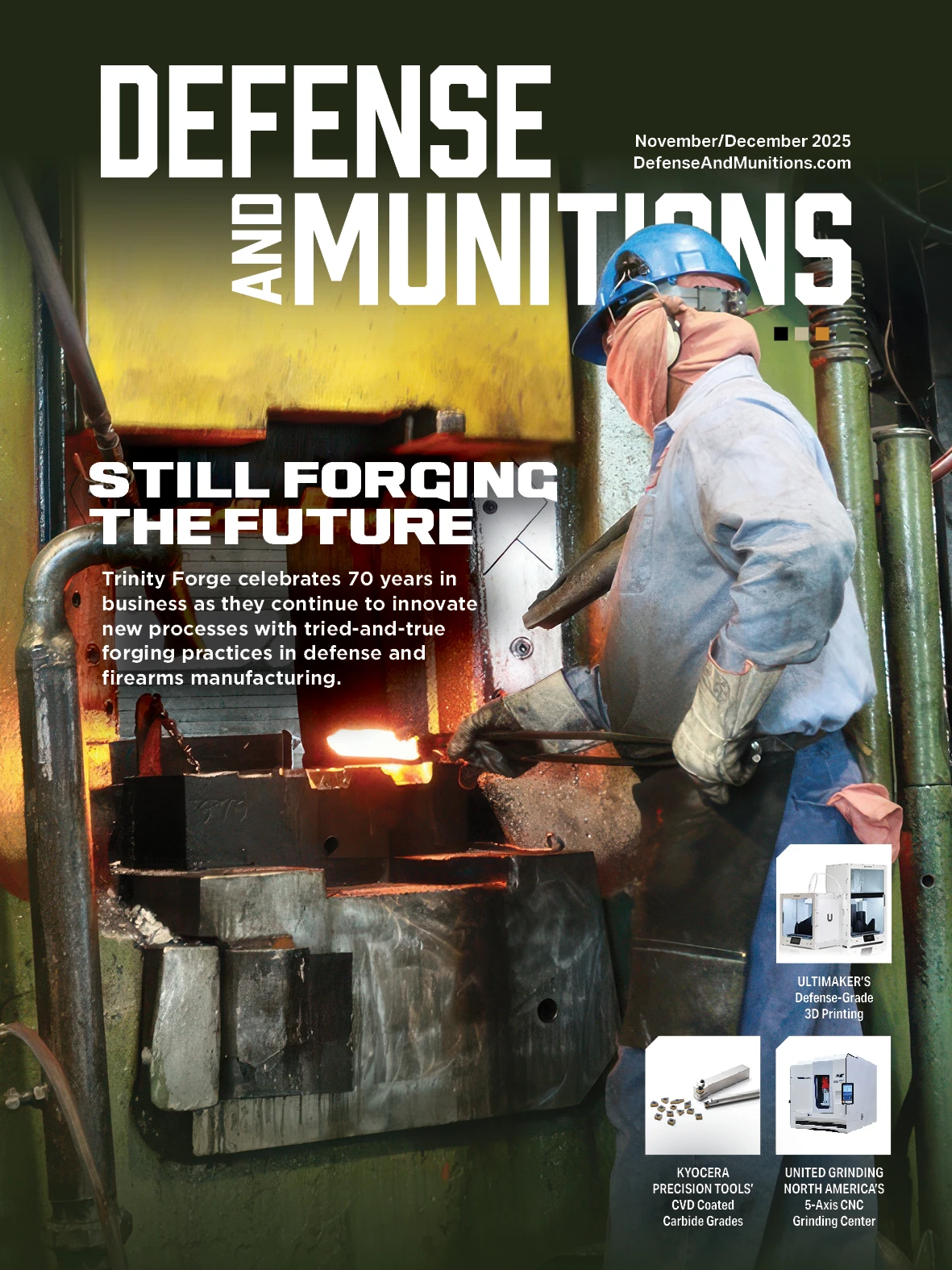

Explore the November/December 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- US Navy selects L3Harris Red Wolf for Precision Attack Strike Munition program

- Snowbird Technologies integrates Meltio Engine Blue into containerized hybrid manufacturing system for defense

- Precision Additive's PA-300 LPBF 3D metal printer

- BIG DAISHOWA supports future of manufacturing with Tools for Schools program

- Mission-Ready: Hutchinson Aerospace & Industry achieves CMMC Level 2 certification

- Shotling's anti-drone shotgun

- ACMI breaks ground on first national manufacturing campus in Indiana, pioneering new model for American defense production

- December 2025 U.S. cutting tool shipments totaled $215M