A history of focused customer solutions

In 1927, the Lawton family started Star Cutter Co. in Detroit, Michigan with a foundation in the automotive industry producing gear hobs and form relief milling cutters for the Big Three automakers. After excelling at this, Ford, GM, and Chrysler began asking Star Cutter to expand support to other products which led the company’s initiative for vertical integration. To avoid the difficulties of relying on external companies to meet customers’ objectives, Star Cutter often would develop needed technologies internally including materials, grinding, and other advancements in cutting tools. Those innovations provided solutions not only for the customer but were routinely used internally as well.

Today, each Star Cutter production facility specializes in certain products and services – carbide blanks and preforms, solid carbide tools, gundrills, PCD tooling, gear cutting tools, and multi-axis CNC tool and cutter grinding machines.

In total, the integration of these related technologies helped Star Cutter become a more complete provider and competitive company. The control of materials, integration of technology and machines, and design advancements have continued to help to control costs and provide value for customers in automotive, medical, energy, off-highway, aerospace, and defense industries. With sales, manufacturing, and distribution strategically located to best serve customers, Star Cutter is a truly global supplier deeply rooted in the United States.

A proud American manufacturer

Star Cutter employees are bound by a mantra that says, “we find a way or make one,” and that spirit of commitment and innovation has propelled the company through the decades for nearly one hundred years. Star Cutter remains privately held by the Lawton family and is based in Farmington Hills, Michigan, with 15 facilities, and more than 750 skilled professionals.

Defense and Munitions will cover Star Cutter integrated products and services in upcoming issues as the company heads toward a century of manufacturing in the United States.

Making the grade with H.B. Carbide

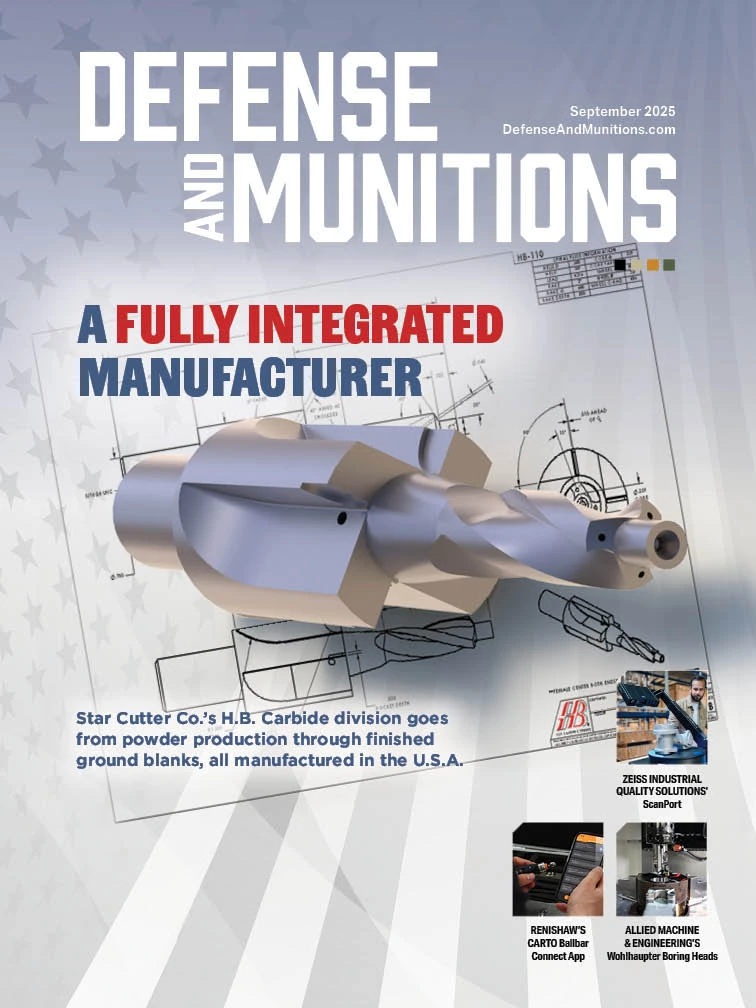

For Star Cutter, serving the needs of the defense industry often begins at the material level. Through its H.B. Carbide division, a comprehensive collection of grades is available in custom, altered standard, and standard blanks and preforms. In total they deliver reliable near net shape solutions addressing customer application needs, challenges, and time to market.

In defense and aerospace manufacturing, material integrity is non-negotiable. H.B. Carbide meets this challenge with metallurgical expertise, rigorous process control, and specialized inspection at every step. Their solutions support a wide range of applications, from military aircraft, ground defense, and space exploration to shipbuilding, firearms, and munitions manufacturing. Carbide grades are developed for critical tooling such as ammunition dies, casing and bullet dies, and gundrills – each optimized for the customer’s exact requirements.

“Our mission is to deliver speed, performance, and reliability,” says Jon Wyniemko, H.B. Carbide’s director of global sales. “We produce precision blanks in the optimal carbide grade, getting customers as close as possible to their finished tool geometry to minimize final material removal. That includes blanks with or without coolant holes, as well as features such as fluting, pre-fluting, pockets, and cylindrical diameter grinding, to name just a few. Our role extends beyond manufacturing, we work closely with customers to ensure every solution is optimized, from grade selection to blank specifications.”

“H.B. was established to provide our foundation of success in the carbide blank substrate business to support customers and as an integrated step for our own finished tool operations,” says Jon Dreher, H.B. Carbide’s general manager.

Whether supplying carbide blanks for large aerospace and defense OEMs or working in tandem with standard tooling providers, and even custom projects in low or high quantity requirements, H.B. Carbide knows every day can be different.

“Every day brings new challenges as we produce both standard and custom tooling with varied order quantities, managing diverse part types and materials to meet unique customer requirements,” Dreher says.

A controlled process for efficiency, the environment, and worker safety

As an ISO 9001:2015 Certified company, quality leads the process from the beginning. Exact measurements and grain sizes of carbide, cobalt, and other metallurgical compounds are combined in specific portions to make the 14 grades offered. The company’s process is built on a disciplined approach, where quality control begins with the selection of trusted raw materials and continues through final inspection.

Skilled teams oversee operations with a focus on uniformity from batch to batch, supported by well-defined procedures and regular evaluations. This attention to detail helps the company deliver products that perform reliably in demanding environments, where failure is not an option.

Efficiency is equally important. H.B. Carbide maintains streamlined workflows and working stock to keep lead times short without sacrificing precision. The result is a balance of speed, accuracy, and value – a combination customers have come to depend upon.

In addition to quality and efficiency, the company prioritizes environmental responsibility and workplace safety. Comprehensive safeguards and modern facility controls help create a safe, healthy, and compliant working environment while supporting sustainable manufacturing practices. With a process grounded in reliability, consistency, and continuous improvement, H.B. Carbide has established itself as a trusted manufacturing partner for industries where performance and precision go hand in hand.

An integrated value proposition

As part of the vertically integrated Star Cutter family, H.B. Carbide’s “from powder production through finished ground blanks” approach serves as a foundation for custom and standard tooling solutions to meet the needs of defense and aerospace manufacturing. The materials expertise and knowledge base within H.B. Carbide support Star Cutter’s Round Tool Solutions, beginning with an understanding of feed, speed, workpiece material, and cycle time requirements. Tools are designed with the required geometries and coolant-hole configurations and produced with the appropriate carbide grade for milling, drilling, or reaming. Production and reconditioning are carried out on Star Cutter’s CNC tool and cutter grinders, which can manufacture a range of tooling including end mills, high-performance drills, drill points, step drills, form tools, medical tools, inserts, gear tools, and other custom designs. This vertical integration helps ensure consistency, precision, and quality throughout the entire process.

Star Cutter and H.B. Carbide represent the intersection of heritage, innovation, and capability – ready to meet the evolving needs of today’s defense industry.

Star Cutter Co.

https://starcutter.com

H.B. Carbide

https://hbcarbide.com

Explore the September 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Defense and Munitions

- Xact Metal names Mark Barfoot VP – Global Sales

- REGO-FIX appoints Joshua Burnett Midwest Territory Sales Manager

- Accutek and Diebold's PTI63 (CAPTO C6) and PSC63 (CAPTO C6) shrink-fit holders

- Mazak Ez machines showcase affordable performance at Expo Manufactura 2026

- New Mazak Phoenix Technical Center opens for business

- Guill Tool's Unicam extrusion crosshead

- Hypertherm Associates invites North American schools to apply for Spark Something Great education grant

- PteroDynamics, AV demonstrate integrated EW capabilities on Transwing VTOL UAS at U.S. Navy Silent Swarm 25 Exercise